Optical distortion is something vision system builders will inevitably have to deal with at some point. When working with wide angle lenses, curvature is always present to some degree with the exception of specialised rectilinear lenses, which are designed with constraints that limit barrel distortion.

These constraints make the optical design more complicated, requiring more internal lens elements and generally a more expensive lens. However, rectilinear lenses, by removing barrel distortion, are a good choice for applications such as aerial mapping, navigation and controlling a robot arm, according to Mark Peterson, VP of advanced technology at Theia Technology.

Geometrical barrel distortion causes straight lines in the image, such as part edges, to curve on the image sensor. As a point moves further from the optical axis, that point gets compressed in the image. A straight line becomes a curve, because each point on the line is a different distance from the optical axis of the lens. In barrel distortion curvature is inward, while pincushion distortion found in telephoto lenses gives outward curvature.

In aerial mapping, for example, barrel distortion makes it more difficult to map and match images side by side. In addition, barrel distortion will reduce the resolution at the edge of the image, which means information is lost if the image isn’t a high enough resolution to begin with.

A rectilinear lens, on the other hand, will give an image with higher resolution at the edges, although the increase in resolution at the edges means that resolution elsewhere must decrease.

Barrel distortion can be corrected using software, but this takes time and processing power. Peterson noted during his presentation at AIA’s International Vision Solutions Conference that some applications, such as mapping, navigation, and controlling a robot arm, could benefit from the faster and lower power option achieved with a rectilinear lens.

Theia has three families of lenses using its Linear Optical Technology for correcting barrel distortion. The widest is a 135° field of view model, which has seven per cent residual corner distortion – a typical lens will have 60 to 70 per cent distortion. The SY125 lens is for a 5-megapixel, 1/2.5-inch sensor, although Peterson said the technology isn’t limited in terms of sensor size.

The other two lens families – both 120° fields of view – are very close to rectilinear, with less than one per cent distortion; those would be ideal for mapping applications, Peterson said.

Nasa is using Theia’s widest angle rectilinear lens onboard the Global Hawk weather survey unmanned aircraft. The lens provides an undistorted view so that the images from the drone show the natural curve of the Earth. Arri, which produces cameras for filmmakers, also uses Theia’s Linear Optical Technology.

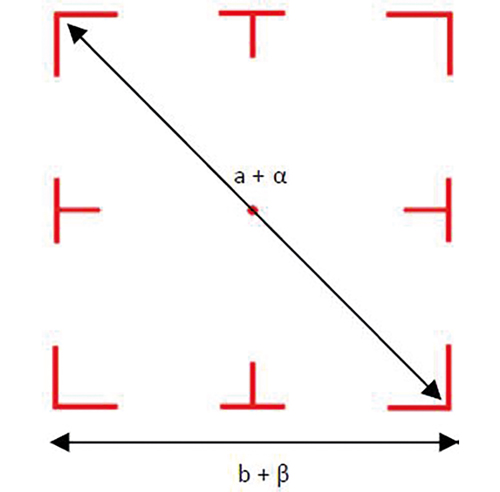

Peterson explained that finding the position of an object’s point on the sensor is simple when using rectilinear lenses.

Knowing the position is important for controlling a robot arm, for example, where the exact angle of the object has to be known.

He said that as the field of view increases, the optical designer must put more weight on rectilinear constraints at the expense of other constraints, such as focus quality or cost. For fields of view of up to 60°, it’s fairly easy to correct for barrel distortion.

Moving to wider fields of view of 100° or more, two examples of rectilinear lenses are Canon’s EF 11-24mm, which has a 115° field of view at f/4, and the Kowa LM4HC lens, that has 112° field of view at f/2.4.

Peterson said that, with wider fields of view, at some point it becomes too difficult to maintain the rectilinearity. Wider fields of view require a larger asphere at the front of the lens.

The asphere is often the largest element in the system and it’s usually one of the most expensive. In addition, it needs to be a precision glass moulded asphere, Peterson noted – plastic elements have problems when it comes to the optical coatings, he said. Canon uses four mildly aspheric elements inside its lens, while the Kowa lens has a large asphere at the front, according to Peterson.

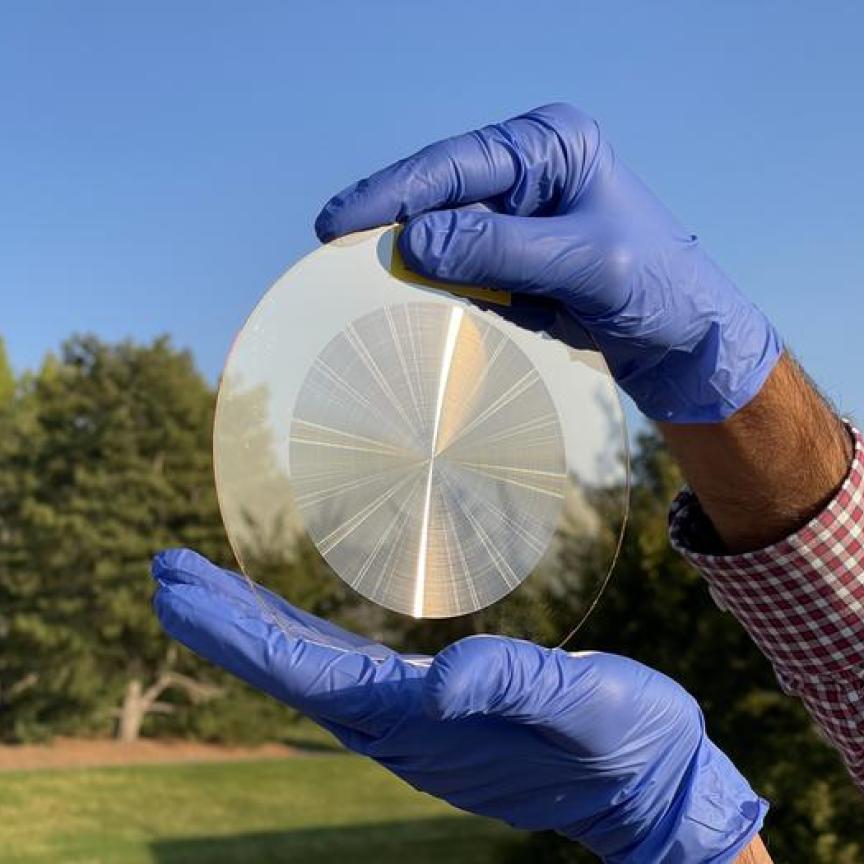

Theia maintains a small lens design thanks to its Linear Optical Technology. The SY125 1.3mm f/1.8 with 135° field of view is the widest rectilinear lens available, according to Peterson. The SY125 lens uses three aspheres with a design that keeps the diameter small.

One effect of rectilinear lenses, Peterson said – either software or optical correction – is 3D stretching. If the object in the image has depth along the optical axis, the image of the object will appear to be stretched. However, when imaging a flat surface, objects will appear the same size – rectilinear imaging, Peterson advised, is best used to image flat objects onto flat sensors.

--

Latest lens launches

Basler and IDS are two camera manufacturers now offering lens product lines, IDS with 20 new C-mount lenses, and Basler with standard and premium lenses.

IDS’s C-mount lens series provides resolutions of 5, 8 and 10 megapixels, as well as focal lengths of 4 to 75mm and different optical classes. The lenses cover sensor sizes from ½-inch to 1.1-inch. The aperture and focus can be fixed mechanically if required, which ensures brightness and image quality remain constant, even if the lens is exposed to vibration.

Basler’s standard product line has an excellent price/performance ratio – the lenses are priced to correspond to the requirements of many cost-sensitive applications. The lenses are ideal for fast cameras with a lower resolution.

The company’s premium product line is designed and tested for more demanding applications – the lenses offer high resolution, low distortion and low vignetting.

Both product lines support popular image circles of sensors available in Basler cameras, from 1/2.5-inch to 1.1-inch, as well as all common focal lengths. The lenses are equipped with a C-mount, and can also be used with CS-mount cameras with an adapter.

IDS C-mount lens

Other new lenses on the market include the Fujinon TF-MA series for high resolution three-chip colour cameras, and Kowa’s FC24M series for 24-megapixel cameras with a chip size of 1.1 inches (see featured product below).

The three C-mount Fujinon TF-MA lenses from Fujifilm are optimised for precise measurement and inspection tasks. The design of the series, which has focal lengths of 6, 14 and 25mm, gives excellent colour reproduction and optical resolution.

Three-chip colour cameras incorporate a prism block as a beam splitter and use bandpass filters that distribute the incident white light to three beam paths for red, green and blue. Each colour channel uses a separate image sensor. The camera construction requires an assembly accuracy in the subpixel range. As such, the lenses used in these cameras must provide excellent imaging properties.

Fujinon TF-MA lenses

Fujinon TF-MA lenses deliver high image quality with consistent sharpness from the centre to the corners, as well as a low level of distortion.

Their design allows working distances of 100mm for the 6 and 14mm lenses, and 200mm for the 25mm lens. The 6mm lens measures 48 x 62mm, while the 14 and 25mm lenses are 34 x 63mm in size.

All three lenses give optimal image quality on 1/1.8-inch sensors with 2µm pixel pitch. They can also be used on sensors of up to 2/3-inch with 3.45µm pixels.

--

Sponsored: Kowa featured product: Kowa 1.1-inch 24MP lens series optimised for Sony sensors

Kowa has launched a new ultra-high-resolution lens series for 24MP cameras with a chip size of 1.1 inches. The new FC24M series is optimised for a pixel size of 2.5μm and fits perfectly with Sony IMX183, 530/540, 531/541, 253/304 sensors.

The optics are coated with a broadband coating, which effectively reduces glare and reflection effects, and provides high transmission from the visible to the near infrared wavelength.

The series is available in focal lengths of 6.5mm, 8.5mm, 12mm, 16mm, 25mm, 35mm and 50mm.

The new Kowa C-Mount lens series is designed for use in industrial environments: The 1.1-inch lenses are compact, robust and temperature resistant.

Contact Kowa for a test: lens@kowaoptimed.com; further information: www.kowa-lenses.com

--

Sponsored: Frankfurt Laser Company (FLC) featured product

FLC offers a great variety of Diffractive Optical Elements (DOEs). The different types of DOEs (beam-splitters, pattern generators, kino forms, beam shapers and gratings) utilise a microstructure surface relief profile for their optical function. Light transmitted by a DOE can be reshaped to almost any desired distribution, just by diffraction and the subsequent propagation. The DOE only encodes the shape of the desired intensity pattern but maintains other parameters of the incident light source (e.g. beam size, divergence, polarisation). Due to their design flexibility. DOEs can have optical functions which otherwise cannot be achieved at all, or only with complicated optical systems. Furthermore, compared to refractive optical elements, DOEs are typically much thinner and lighter, making them an attractive replacement in a number of applications. With the standard size of 8mm in diameter and 0.63, 1 or 1.2mm in thickness, these elements fit well into numerous standard laser modules.

https://frlaserco.com/Products/Optics/Diffractive-Optical-Elements-DOEs