For 20 years now, AT – Automation Technology has repeatedly made a name for itself as a pioneer in the 3D image processing industry and is constantly developing new innovations in the field of special sensor technology. Like now. As part of the first product launch of its new 3D C6 series, the technology company from Northern Germany recently integrated the globally unique feature MultiPeak into its new cx4090HS sensor module, which for the first time will enable noise-free recording of 3D profile data via laser triangulation for the first time.

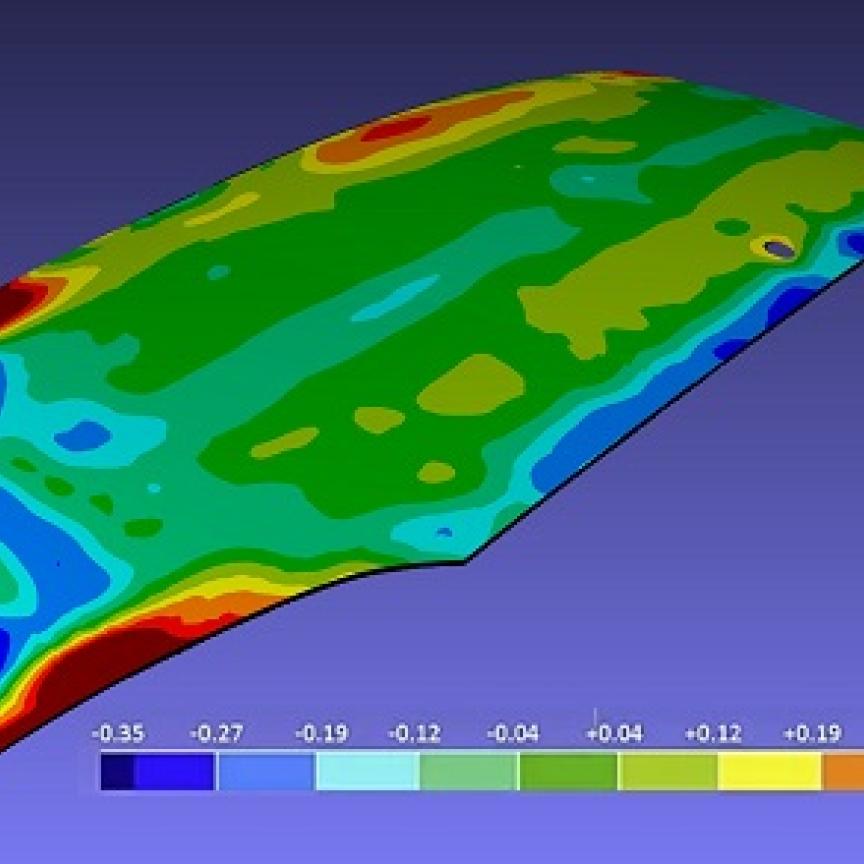

Thanks to MultiPeak, highly reflective materials such as metal, plastic or glass can be scanned without interfering reflections. If several laser reflections exist on the inspection surface, the MultiPeak feature helps to distinguish between them and to output up to four profiles with peak data separately. In this way, multiple laser reflections can be easily checked for plausibility on the application side and, if necessary, eliminated from the evaluation data as disturbance variables. The major advantages: The customer receives a clean profile evaluation and can thus significantly improve his quality control.

In the automotive industry, for example, MultiPeak is used for weld seam inspection of V-shaped steel sheets. When measuring glass plates, this feature in turn provides information about the thickness of the glass surface. The new function in the new AT 3D sensor module thus offers the decisive advantage for scans on all types of reflective materials across all industries and also provides customers with significant added value for their process optimization due to its worldwide uniqueness.