AI, 3D imaging and precision optics dominated the automation landscape at this year’s flagship robotics fair.

Held in Munich from June 24 to 27, automatica 2025 brought together over 750 exhibitors and visitors from more than 100 countries, offering a sweeping view of how robotics, AI and automation are reshaping industry. For the imaging and machine vision sector, the event delivered both a spotlight and a stage.

automatica 2025 ran from 24 to 27 June at Messe München (Image: Messe München GmbH)

That stage was the Machine Vision Pavilion. Co-created with the VDMA, the Pavilion provided a focused platform for AI & Vision, 3D imaging, bin picking and robot vision, with deep-dive discussions at its Vision Expert Huddles. Rather than remaining limited to its home space, however, imaging tech was everywhere during the fair: in real-time inspection, autonomous guidance and collaborative robot safety systems. For Europe’s manufacturers, vision is fast becoming the eyes of intelligent automation.

Machine Vision Pavilion (Image: Messe München GmbH)

Fraunhofer institutes: vision at the cutting edge

A standout presence across the show, multiple Fraunhofer institutes demonstrated how imaging underpins automation – from cognitive robotics to sustainable e-waste recycling, here are some stand-out works, presented by Fraunhofer:

Fraunhofer IFF: smarter robots = safer workspaces

Fraunhofer IFF revealed AI-powered cognitive robotics that uses camera vision to recognise and adapt to unknown objects in real time – no pre-training needed. Meanwhile, the PARU safety system projects visible light curtains around robots, dynamically monitored by cameras to ensure human safety and compliance. “Our technology is unique,” said Norbert Elkmann of Fraunhofer IFF, highlighting its ISO/TS 15066 adherence. Also presented was Fraunhofer IFF’s package of computer-aided safety (CAS) solutions, which further simplify compliance for collaborative robotics.

Computer-aided safety helps with planning, risk assessment and safety approval (Image: Fraunhofer IFF)

Fraunhofer IFF: vision-guided electronics recycling

Another development presented by IFF was its iDEAR project, which combines 3D imaging and AI to automate electronics disassembly. High-resolution cameras and spectral sensors scan devices to detect screws, classify materials and build digital twins for each product. According to IFF, this enables robots to execute precise, tool-changing disassembly – recovering valuable components from e-waste without manual input. “We want to revolutionise the disassembly of e‑waste,” says project lead Dr. José Saenz.

The robot lifting the motherboard out of the housing (Image: Fraunhofer IFF)

Fraunhofer IWU: imaging in motion

Presenting its GreenBotAI system that blends fast vision and energy-efficient robotics, Fraunhofer IWU explained how cameras are used to capture 3D images of moving components, which allow robots to handle and assemble without stopping. The robot predicts motion, selects grip points and inserts parts – like rivets – on the fly, guided only by visual data. Combined with real-time force analysis and a digital twin, Fraunhofer IWU says the setup boosts both productivity and energy savings by up to 25%.

Guided by 3D data, the robot picks up a clip and inserts it into a moving part (Image: Fraunhofer IWU)

Fraunhofer IOF: seeing the invisible

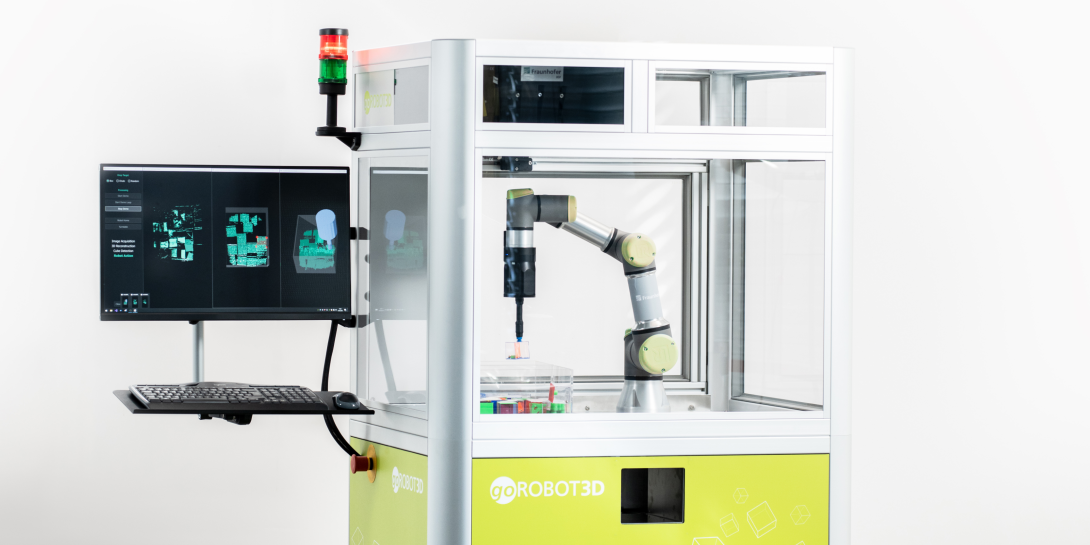

goROBOT3D, a thermal imaging system that detects transparent, dark or reflective objects in under two seconds, was presented by Fraunhofer IOF. Using a single pair of thermal images and diffractive optics, IOF says the system delivers high-speed 3D data, even on tricky surfaces. “Instead of capturing several hundred pairs of images,” says Dr. Martin Landmann, IOF research scientist, “our method can reconstruct the 3D information with just one,” enabling continuous bin picking and handling without cycle interruptions.

The goROBOT3D uses intelligent thermal imaging to capture and process materials (Image: Fraunhofer IOF)

Technology in the aisles: imaging highlights from industry exhibitors

Fraunhofer wasn’t alone in spotlighting imaging breakthroughs. Across the show floor, leading vendors brought practical, deployable solutions that push machine vision to new heights.

automatica 2025 (Image: Messe München GmbH)

MVTec: vision software built for automation

AT MVTec’s booth, demonstrations of its HALCON, MERLIC and Deep Learning Tool platforms included solutions such as OCR, defect detection, barcode reading and Deep 3D Matching – blending traditional and AI methods for resilient bin picking. “AI for industrial machine vision is made in Munich,” said Dr. Olaf Munkelt, Managing Director of the Munich-based company.

OPT: multi-angle imaging and AI precision

OPT Machine Vision showcased a range of inspection and guidance systems at the fair, including its 2.5D programmable pattern light system, which it says tackles reflective surface defects, while an FPGA-powered 3D picking solution uses laser profiling and edge AI for rapid, sub-millimetre positioning. “Our solutions align with the precision demands of Western manufacturers,” said OPT, highlighting their role in advanced automotive and electronics inspection.

OPT Machine Vision (OPT Machine Vision)

Vieworks: dual imaging and high-sensitivity cameras

Unveiling its latest dual imaging TDI line scan camera – the VTD-16K5X2 – Vieworks suggested It can half inspection time by capturing two images in single scan. According to the company, the back-side illuminated VT Sense series enhances imaging across visible, UV and NIR spectrums, and co-developed lenses from Schneider Kreuznach complete the vision package for inspection environments.

Mech-Mind: high-speed AI + 3D vision systems

Including registration-free picking and DOT code reading, Mech-Mind’s AI + 3D vision demos at Automatica were some of the most varied. The exhibitor revealed how their “Eye + Brain” systems uses structured-light and laser profilers to guide robots through a chaotic part handling process with minimal training, and how its systems can deliver precise 3D imaging, even at distances over three metres – ideal for large EV parts and reflective surfaces.

One of Mech-Mind's demos at automatica 2025 (Image: Mech-Mind)

ABB: AI vision driving autonomous robotics

ABB framed imaging as central to its “Autonomous Versatile Robotics” strategy at the fair, stating that vision systems now let mobile robots perceive, plan and re-plan tasks in unstructured environments. OmniCore™, ABB’s new modular control platform, and its AI-enabled vision software were both on display in Munich, powering real-time autonomous picking, fault detection and Visual SLAM navigation with mm-level accuracy. “We’re combining all the senses robots need,” said ABB Robotics President Marc Segura.

IT+Robotics: 3D toolpath planning made simple

IT+Robotics debuted EyeT+ Adapt – a surface finishing system that uses 3D vision to auto-generate toolpaths for tasks like grinding or polishing – at the fair, explaining how it “transcends the limitations of traditional methods,” according to CEO Stefano Tonello. Explaining how the system scans, then adapts to each unique workpiece, IT+Robotics says it eliminates manual programming, and enables flexible, high-quality finishing in low-volume or high-mix environments.

There was a lot to take in across four days of automatica 2025, but one lesson was made abundantly clear: machine vision is no longer a supporting technology, it’s the engine that’s driving flexibility, safety and intelligence in next-generation automation. Whether they’re enabling robots to adapt, inspect or collaborate, vision systems are central to how we build, inspect and interact with machines.