Packaging lines are working with smaller batch sizes, a trend that vision is both aiding and having to respond to. At the same time, new vision technology such as hyperspectral imaging is finding its way onto packing lines, with UK-based automation specialist Brillopak, which has begun integrating the technology into robotic packing and palletising systems.

Hyperspectral cameras can vary from those covering distinct bands and giving extended colour information, to those recording spectral data across a wide range of the electromagnetic spectrum. The technique is able to detect minor blemishes and defects on food, for example, such as bruises on apples or burnt areas on cooked items.

Brillopak intends to use hyperspectral imaging between packing and case loading operations, where human workers have previously inspected food packs, rejecting any that don’t meet quality standards. Workforce fatigue and human error has meant that on fast packing lines, even visible defects, such as bruising and blemishes, can be missed. ‘Today’s hyperspectral vision systems are programmed to have a level of impartiality that human eyes just don’t have,’ said Brillopak director David Jahn. ‘With many end-of-line packing stations now automated and processing in excess of 100 packs of produce a minute, incorporating vision is becoming increasingly commonplace.’

Brillopak says that more automated quality inspection will be used in packhouses that have previously relied heavily on EU migrant workers, but are now experiencing staffing pressures because of Brexit and the pandemic. Such pressures have been building, as the availability of labour has declined steadily since the 2016 Brexit vote, but now, with the pandemic, staff can no longer work in close contact with each other. Both factors have conspired to challenge packers, who often do not have the space to accommodate social distancing while maintaining production levels. For Brillopak, automating such quality inspection presents an obvious solution.

To help minimise the risk of an out-of-spec product heading out of the factory doors and onto retailers’ shelves, Brillopak has begun to integrate hyperspectral imaging as an option on its Unipaker robotic crate packing systems. This, and other vision technology, will improve the accuracy of how products are picked and presented to the packing robot at speed.

‘Using cameras we can find the centre and orientation of products,’ said Jahn. ‘This information is conveyed to the robot, which accurately responds, adjusting its speed and position to pick up the pack, regardless of location on the conveyor. The result is fewer line stoppages to address bottlenecks and better presentation in the retail crates.’

Smart cameras such as Sicks’ Inspector P camera can carry out different tasks simply by uploading new software apps. Credit: Sick

Brillopak incorporates vision for appraising labels, packaging condition, print inspection, position detection with 2D and 3D imaging, and barcode and data code reading. Although still a relatively small adopter of hyperspectral technology, Brillopak expects food processing and agriculture to benefit significantly from advances in the imaging technique.

‘With food safety, quality assurance and food waste so high on the agenda, we anticipate that hyperspectral imaging will soon become the go-to vision system on food processing lines in the future,’ confirmed Jahn.

Raise a bottle

Danish firm Novio Packaging has turned to machine vision to achieve a flexible quality inspection system that can cope with changes in the types of bottles it produces.

Using a vision solution supplied by Omron, Novio Packaging is now able to cope with rapid changeovers and can meet customer demands for a wider portfolio, involving smaller but more variable batches. This also helps to avoid any delays in the development of new products.

Novio initially explored systems that proved to be ineffective, as they were insufficiently accurate and users couldn’t make adjustments or programme the software themselves. It was looking for a solution that could successfully eliminate defects down to one bottle out of 100,000.

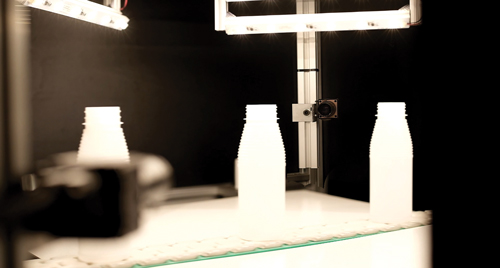

The solution from Omron combines the firm’s FH vision system, as well as its FQ2 cameras. The system incorporates lights and cameras set at different angles from all sides so that they can detect any defects, such as scratches or dust, that would affect the quality of a bottle. Any bottle identified as having defects is automatically discarded.

The Omron vision system is very precise, scalable, and adaptable, and can easily cope with changes in production. It also has a single software program that Novio employees can configure with ease.

Peter Lykke, Novio Packaging’s technical manager, said: ‘After I’ve carried out the basic programming and set up the cameras, our technical staff can easily adjust the program for new types of bottles themselves.’ This saves Novio time and money, with no need to call in a specialist or a systems integrator to handle any changes.

Ease of programming is something that vision provider Sick is aiming for with its AppSpace software platform, which the company is supplying for automating new, increasingly flexible packaging lines. The company has worked with a European food packager that supplies supermarkets, which is capable of carrying out single-figure production runs, enabling it to deliver tailored orders. In a world of sustainability this means less waste. If products can simply be made to order, companies no longer have to worry about making large batches of products just to cover potential – rather than guaranteed – orders.

Cameras inspecting bottles for defects from multiple angles. Credit: Omron

‘This is having an impact on how we, as vision firms, are developing our technology,’ remarked Neil Sandu, the new chairman of UKIVA and Sick’s UK product manager for imaging, measurement and ranging. ‘We are having to design our systems to be equally as flexible as modern production technologies, to better meet challenges posed by production and packaging.’

Sandu explained that, rather than having long production lines for single types of product, autonomous mobile robots can now transport different types of product around a factory for processing at different workstations. ‘This enables single production systems to process multiple types of product, rather than one system being required on each different production line,’ he said. ‘The traditional production line is transforming into a production matrix, with its different workstations dotted around the factory floor.’

Sandhu said that Sick is moving to more general solutions that can be tailored to a wider range of tasks, and be configured easily without specialist knowledge in machine vision. Rather than having to design a camera for new tasks, the company will instead develop a software app to add to its AppSpace platform. The apps can then be downloaded directly onto a smart camera and configured from a web browser.

‘In doing this, our cameras can be flexible enough to move with the times in production and packaging,’ said Sandhu.

He said that a camera with a label-checking app, for inspecting best-before dates or label position, could be redeployed with a robot guidance app that lets it be used in a different part of the factory for pick-and-place tasks.

Sick has had to employ software developers and create branches of its business to deal directly with software, according to Sandhu. He noted that multiple vision firms are going down the app development route, although he said this does not mean traditionally hardware-oriented vision firms, such as Sick, are now looking to take on dedicated machine vision software firms such as MVTec, or software giants such as Microsoft. Sandhu said that Sick is partnering with such firms to enhance its capabilities.

Multi-purpose 3D

In warehouse automation LMI Technologies says the logistics sector has undergone a shift from assessing shipping fees strictly by weight, to also charging by dimensional weight. It means LMI’s 3D profilers are now being used to measure box dimensions, as well as to scan open boxes to determine fill volume based on 3D height map data.

The firm’s wide field of view Gocator 2490 3D laser profiler, released last year, can be used for both tasks. The Gocator 2490 has a 1m2 scan area, and operates at a rate of 800Hz and 2.5mm resolution in all three dimensions.

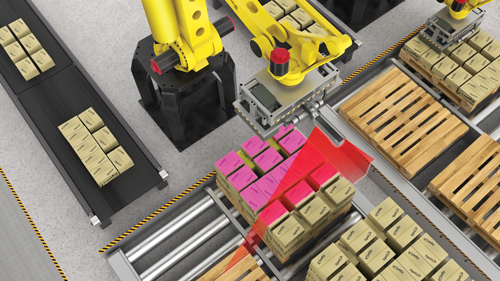

3D sensing can be used in warehouses for inspecting packages and for palletisation. Credit: LMI Technologies

Data from the sensor can be used to sort packages into appropriate locations depending on their size. The same sensor could also be used to determine the fill volume of open boxes, so that individual boxes can be packed efficiently. A third use is for robot palletisation and depalletisation, where the sensor is mounted on a robot arm and gives precise positional co-ordinates to tell the robot which boxes to handle on the pallet. Here, the Gocator 2490 sensor’s wide field of view is able to cover the entire pallet and its contents in a single scan. Robot calibration algorithms are built into the sensor to increase its ease of integration.

In addition to dimensional gauging, packages also need to be inspected for surface defects. Receiving and sorting centres usually conduct this type of quality inspection, checking for surface defects such as dents, tears, punctures and folds. The 3D sensors can be used here too, to scan the exposed sides of boxes travelling on a conveyor, providing real-time defect detection to flag damaged packages. Pass/fail control decisions are stamped with time and position information for every box, with each decision tag representing an outcome to be communicated to downstream sorting equipment.

As if that wasn’t enough to demonstrate the flexibility of modern 3D smart sensors, the same systems can also be used for scanning barcodes to ensure traceability in logistics. Built-in software running in LMI’s Gocator sensors enables engineers to scan and read data encoded in 1D barcodes or OCR data from a 3D scan, without the need for 2D vision cameras or specialised barcode readers. The flexibility of vision devices is making them much more attractive as a tool to help automate packaging lines and warehouses alike.