Explain the technology that won the EMVA award.

Three dimensional digitisation is the backbone of 3D quality inspection, as well as an important issue in Industry 4.0. This work solves the 3D reconstruction problem by using the CAD model as a guide or proxy. With the introduction of this prior model, many parts of the existing 3D digitisation pipeline are enhanced.

The input is a set of laser scans or point clouds and a CAD model. The algorithm starts by detecting the pose of the CAD model in each acquired scan, and in doing so identifies the pose of the scanner. In this way, scanned 3D points belonging to the CAD model in each shot can be brought into one common coordinate frame. Moreover, the links between the cameras and the 3D coverage of the object can be computed automatically.

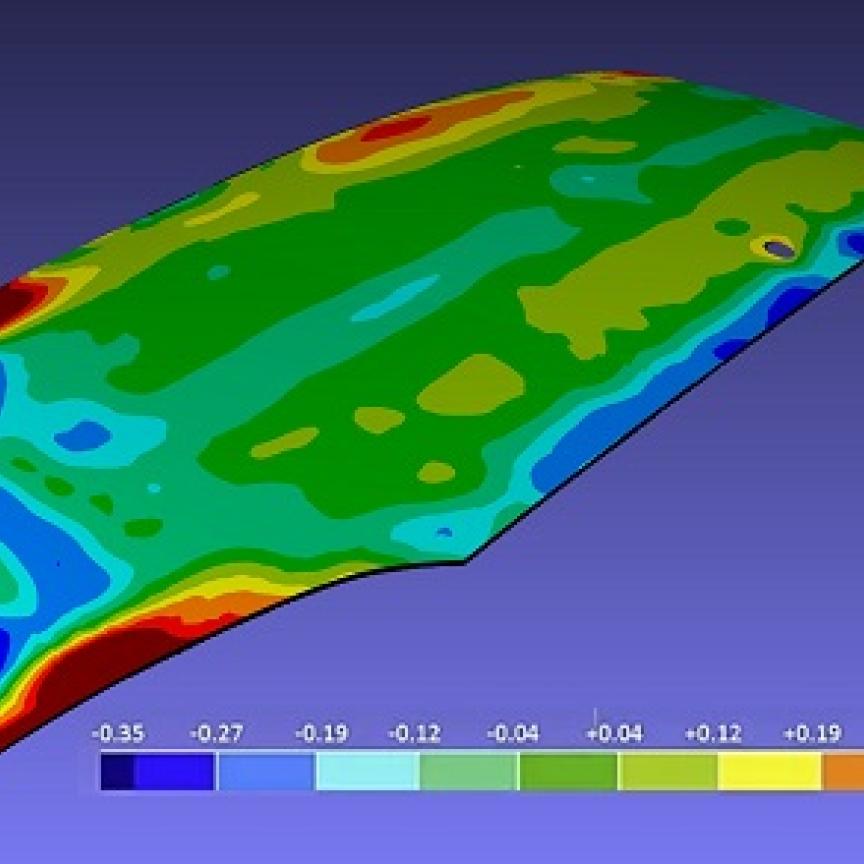

In the final stage, deviations mean the real scene in the CAD prior is discarded and a multi-view global optimisation is conducted, resulting in a final consistent 3D reconstruction. This, to the best of my knowledge, is the first time the CAD model is used as a prior to guide and simplify the reconstruction procedure.

How can this be applied to solve real-world vision applications?

Many production lines aim to manufacture physical instances of ideal CAD models as closely as possible. Three dimensional reconstruction is used to capture the 3D structure of the produced part, for verification against the CAD model. Conventionally, an operator acquires a set of images or scans and an algorithm automatically stitches those into a reconstruction. This, unfortunately, requires careful data acquisition, a lot of offline computations, and cannot supply the operator with live information.

This work proposes the same style of data acquisition but, with our method, large parts can be captured quickly and accurately, and online feedback is provided on site. The project also presented a case study in which gas turbine casings – which are very large, heavy, and non-moveable – are digitised. Thanks to the method’s intolerance to occlusions and clutter, and its ability to give online feedback, it is able to perform in-place inspections without sending data to laboratories.

What are the benefits of winning the award?

In my perspective, the award signifies that the work is of benefit to an important and highly qualified community. This is an invaluable personal reward. Being selected by the renowned EMVA jury legitimises the worth of what I do and gives me huge encouragement.

Moreover, the EMVA is made up of individuals and companies from all over Europe, creating an exclusive machine vision network. Getting introduced into such a network is certainly an honour and holds great potential for my future career.

How could ties between academia and industry in Europe be improved?

Europe, and especially Germany, is one of the few regions in the world where industry-academia collaboration is comparatively strong. This awarded work, developed in collaboration with the Technical University of Munich and Siemens, is a good example of this tie. However, as always, there is a lot of room for improvement.

Today, the concerns of industry and academia are very different. While the research community considers more commodity-related problems, industry has application-specific details and controlled environments. While the goal of research is to outperform the state-of-the-art – which might be far from ideal – industry seeks practical, repeatable, accurate and solutions that work. With such a contrast, it becomes a long road from research to industrial applications, requiring significant engineering effort.

I think both parties have a lot on their shoulders to lower this bar. Industry should be more courageous in entrusting academia with studies and initiate more projects with better support – such as data or platforms – while academia should be more open to the necessities of industry, rather than solely trying to solve the problems of a current trend. If academic scholars were to keep the goals of industry in mind during the design of their solutions, I believe that the results would be more beneficial to industry. However, it is also industry’s responsibility to educate and inform their colleagues in academic communities of their concerns and priorities.

What are your future plans for this work?

I have a passion for computer vision and especially 3D computer vision, so any prospective work will probably be along these lines. The exact form is yet to be seen. However, first, as I’m a strong supporter of the link between academia and industry, it is certain that, regardless of whichever path I pursue, I will be holding onto the collaborative method of working. Second, there are breakthroughs occurring in the field of artificial intelligence, and my future work could involve the use of such technologies in computer vision.

I’m open to promising – and fresh ideas – for projects, joint work or any form of collaboration.