The successful implementation of a machine vision system requires illumination and camera performance to generate images that can be unequivocally graded by the image processor. When calibrating a machine vision camera, there are three main aspects of performance that should be characterised and corrected for optimal image quality.

The first is spatial characteristics. Optical path distortions, variations in pixel-to-pixel sensitivity, defect pixels, fixed pattern noise: these effects are all inherent to a greater or lesser extent in all imaging systems, conspiring to degrade the generated image.

Secondly, dynamic range. CMOS and CCD image sensors are inherently non-linear, so the camera must control the image sensor to output a linear response. And thirdly, spectral characteristics. Not a concern under monochromatic illumination, but in colour applications spectral mismatch between the source used to calibrate the camera and the lighting used can lead to errors in colour recognition, and therefore errors in processing.

Imaging a spatially uniform light source enables the determination of these parameters. While there are various means of generating a spatially uniform light source, the only instrument that can deliver the superior uniformity and configurational flexibility required here is an integrating sphere.

This is a hollow sphere coated with a highly diffuse reflective white material, typically barium sulphate, including either an internal or external light source and an exit port which is viewed by the camera. Light emitted by the source – baffled to ensure no light passes directly to the exit port – undergoes multiple diffuse reflections in the sphere to generate uniform illumination over the sphere walls and importantly, superlatively uniform illumination across the plane of the exit port.

Integrating spheres are traditionally paired with one or more tungsten halogen light sources to ensure stable light output. Mechanical attenuators or multiple lamps are used to provide a means of varying the radiance of the sphere, without changing the spectral distribution.

While spatial and dynamic range calibration is not dependent on the source used (provided the spectrum of the source does not change in varying radiance over the dynamic range of the camera), the same cannot be said of spectral calibration. Calibrating a camera intended for use with LED illumination with a tungsten halogen source will result in colour error and incorrect object classification.

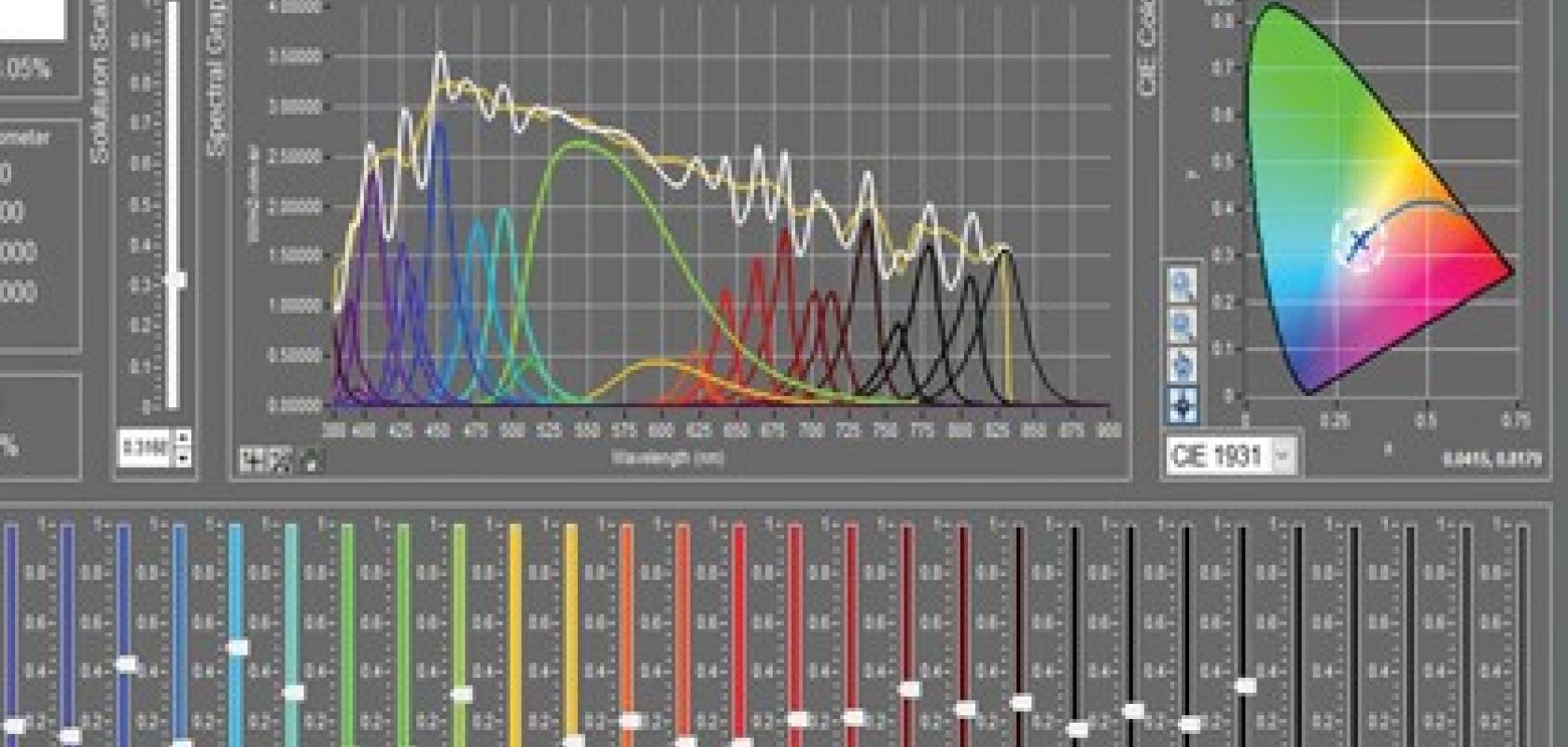

Labsphere has been at the forefront of development of spectrally tunable uniform light sources to enable fully flexible testing of machine vision cameras. The Spectra-FT LED tunable light source offers spectral reproduction in the 390 to 1,000nm range, with up to 84 individual LEDs, while the Spectra-UT polychromator – using DLP technology – offers an excellent level of spectral distribution reproduction. Pro-Lite distributes uniform light sources, reflectance standards and targets from Labsphere.

Finally, for machine vision applications where absolute spectral reproduction is less important, a range of colour-tunable white LED sources can be tuned for colour temperature to better match customer illumination sources, while offering significantly faster stabilisation times than traditional tungsten halogen uniform light sources. This gives faster calibration times for machine vision imagers.

--

Broadband LEDs for hyperspectral imaging

Engineers working with hyperspectral imaging tend to rely on halogen light sources. Now, broadband LED sources covering a more complete operating wavelength range are starting to come on the market, via solutions from Ushio, CCS Group, Metaphase and Prophotonix.

Hyperspectral imaging requires a uniform emission over the wavelength range of interest, which can extend from the visible to the near infrared, 400 to 900nm, and even out to shortwave infrared. White LEDs are not uniform and normally have a peak in the blue region of the spectrum, with a hole at around 480nm and drop off at just over 700nm. An alternative is to use multiple LEDs, but the only practical way to combine enough LEDs for hyperspectral imaging is to combine them into a line scan illuminator. This, however, creates spatial inhomogeneity because the light from different LEDs arrives at different angles.

- Greg Blackman looks at how SWIR spectral imaging can help reduce plastic pollution

- Optical design is crucial in enabling wider adoption of hyperspectral imaging, finds Andy Extance

The CCS Group, Ushio and Metaphase now all offer tunable broadband LED light sources that provide a much more uniform emission spectrum from 400 to 900nm, extending to 1,000nm.

CCS’s hyperspectral bar light

Matthias Dingjan, product manager at CCS Europe, explained: ‘The [CCS] LED solution is a single point light source, and thus all wavelengths come from the same spatial origin, meaning there are no wavelength-dependent angular absorption effects. It can be designed into a wide variety of different form factors, such as back lights, line lights and many more. Each project has its own individual set of specifications and the LED solution for hyperspectral imaging from the CCS Group offers high flexibility to answer the hyperspectral illumination needs of the market.’

He said that CCS has produced several custom products to comply with the needs of different applications. For instance, to increase intensity, the company designed a line light to maximise performance in the visible range, which isn’t a standard product.

Ushio has added an extra 20mW of power to its broadband Spectro LED series. The updated indium gallium nitride chip achieves an output power of 180mW, at 500 to 1,000nm. The 1mm2 chip with SMBB package also features excellent heat dissipation and a choice of lens options.

Developed in Kyoto, Japan, the Spectro series has proved popular in the food and medicine production industries.

For those measuring in the shortwave infrared, Metaphase, CCS and Ushio all offer swir options, with Metaphase providing a broadband light source from 1,000 to 1,600nm, while CCS has light sources with peak wavelengths of 1,050, 1,200, 1,300, 1,450, 1,550 and 1,650nm. Ushio offers multi-chip swir packages, such as its Epitex D series that can house up to three narrowband chips, each emitting a different wavelength.

Prophotonix has also recently launched a hyperspectral version of its Cobra Multispec line light, with a spectral range from 365 to 1,000nm.

The light source has been designed to cover the required spectral range and is balanced to compensate for the sensitivity of hyperspectral line scan cameras operating in the visible to near infrared spectrum.

Smart Vision Lights featured product

Control your machine vision lighting with your smartphone with SmartVisionLink™. A SmartVisionLink™-enabled light, a Bluetooth® module, and the free app are all you need. Improve efficiency by easily controlling your light with the SmartVisionLink™ app on an Android phone or iPhone. Connect your light to a SmartVisionLink™ Bluetooth module, pair your phone to the Bluetooth module, and you’re ready to go. Optimize uptime by adjusting lighting without having to shut down your production line. Manage up to six lights that are either directly connected or daisy-chained together. Set the lighting intensity level for the entire area or for individual zones. Increase safety by keeping both feet on the ground while adjusting your lights, even in hard-to-reach places. With fast, easy lighting adjustments, you’re able to move on with the rest of your day.

https://smartvisionlights.com/smartvisionlink

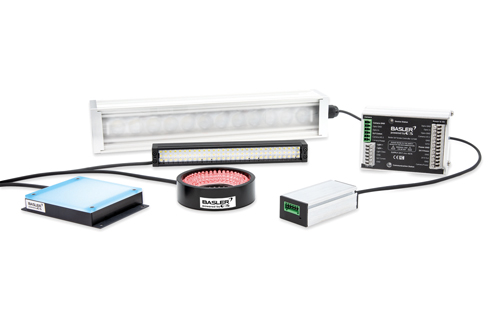

Basler featured product: Intelligent Lighting Synced by the Basler SLP Feature

Basler and CCS, leader in LED industrial lighting, have developed a comprehensive portfolio of intelligent lighting. Unique in the market, the new lighting concepts are designed for selected Basler ace cameras with the Basler SLP feature. This feature enables direct communication between camera and light source with only one software, the pylon Camera Software Suite. Therefore, the complexity of a vision system can be reduced and users can integrate lighting easily and early on, thus shortening the time spent on design and installation.

Offered are two solutions:

• The plug-and-play easy solution using the Basler Camera Light with the built-in SLP Controller. The light and controller are integrated into one product for synchronized operation.

• The flexible solution, where the Basler SLP Controller allows the easy integration of any LED light source (including CCS products) by using the SLP feature.

Laser Components featured product

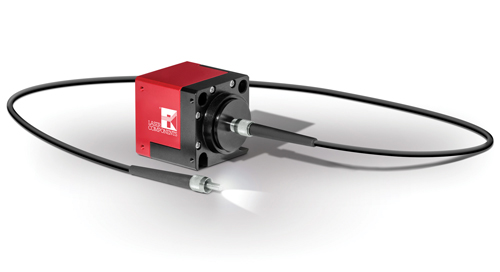

The world’s first laser white light module ALBALUX FM features bright and highly directional fibre optic output for precise illumination in next-generation medical and machine vision applications, including medical endoscopy, surgical headlights, manufacturing processes, and 3D machine vision solutions.

To maximise light transmission and precise beam directivity, optical fibres are incorporated enabling unprecedented >150 lumen CW output with sharp narrow edges, resulting in enhanced vision that provides faster processing times and more reliable monitoring on the manufacturing floor, and improved diagnostics and patient outcome in medicine.

Offering the user full flexibility in both standard and custom configuration requirements, the plug-and-play module features custom-designed electronics to ensure safe operation of the diode.

Despite its high optical performance, ALBALUX FM has low power consumption. Two semi-polar blue GaN laser diodes (450nm) illuminate a phosphorus chip, producing a brilliant, white light that is >10 times brighter than the brightest white LEDs available.

www.lasercomponents.com/uk/product/albalux-fiber-coupled-module/

Other new illumination releases

Chromasens and Gefasoft have both launched illumination controllers. Chromasens’ XLC4 LED controller serves as an external power supply with adjustable current to control brightness. It ensures the optimal spectral behaviour of LEDs by delivering continuous power of 80W per channel and preventing brightness variations in the images. It can strobe at 60kHz, as well as monitor temperature for fan or water cooling.

The XLC4 unit is controlled by a set of ASCII-commands, independent of the electrical interface type. Therefore it is easy to control the XLC4 from any user application with access to either RS232, RS485, USB or Ethernet. This lets the user adjust the light output remotely, since different materials may need to be inspected on the same production line but require different light levels.

The controller can be integrated into new or existing systems using the Chromasens Corona II LED illuminator or third party models.

Chromasens XLC4 unit

Gefasoft’s new Lucon 2 product provides current and voltage control for driving LED lighting efficiently, and minimising heat from the light source. The controller can operate the light in continuous or in strobed mode, with the latter mode generating flashes of up to 5µs and currents of 20A.

Lucon 2 is easy to configure via a web page.

Also new are modular bar lights from TPL Vision, with the option to mount micro-optic diffusers to change the angle of light. TPL Vision’s Modular Bar is a high brightness, homogeneous LED source, with integrated current controller. Combining its Angle Changers – diffusers – with its Curve Effect means hot spots can be eliminated and read rates improved, giving users full control of their lighting application, from short to long working distances (4m or more).