Israel has an excellent pedigree when it comes to computer vision – the autonomous driving firm Mobileye, which Intel bought for $15.3 billion earlier this year, is one of the more high-profile examples of technology developed in the country. Israeli firm Volume Elements specialises in algorithm development for all sorts of vision applications, including industrial inspection and medical imaging, along with airborne drone tasks, satellite imaging, and consumer products that use vision. The company was founded around 10 years ago by Guy Lavi, after gaining industry experience in international corporates as well as Israeli vision-based startups, and realising the growing need for ad hoc imaging experts. Based in Tel Aviv and with around 25 employees, it offers a contract service for developing vision algorithms. The company combines extensive academic knowledge with industrial experience in various machine learning and computer vision fields to develop a solution for the customer. Working in a simplistic retainer mode, the customers set a pace that fits their budget and milestones.

The advantage for the customer of working in this way is that it simplifies R&D work. ‘You don’t have to go through a long period of defining requirements for a project,’ explained Lavi. ‘We try and make it easy for the customer to start developing a prototype. The customer can also stop for a period of time to optimise the product or make management decisions – we can start with one full time equivalent (FTE) and after a period move up to three FTEs, and then have a break until there’s funding or user feedback.’

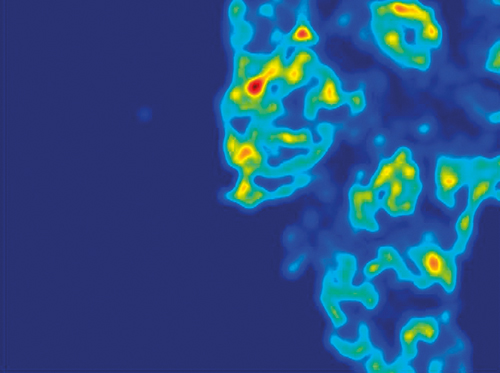

Vision algorithms can be used to map density of active material in plants (below)

Volume Elements’ clients range from small start-ups to large corporate firms. For the small start-ups, Volume Elements can serve as a major part of the customer’s R&D team, using seed funding to get through the first stages of development and reach the next demonstration of a concept. At the other end, Volume Elements might be contracted for R&D work for a big corporate firm facing greater work throughput, or wanting to enter new fields.

‘It’s a much lengthier process and more expensive to build a new R&D team of your own; it takes time to hire people on the one hand, and market needs change during the lifecycle of the product on the other, so you need to adapt,’ Lavi said. ‘Companies find it easier to work with a team that can start within weeks, and where the scope of the project can be adapted quickly. The customer can optimise the amount of work carried out on the project at its different stages.’

Volume Elements has experience with different computer vision disciplines, such as tracking and classification algorithms, recently using deep learning and artificial intelligence, a way of training a machine to classify images using neural networks and large amounts of image data. ‘Deep learning is becoming a commodity and could be considered another tool,’ Lavi stated. ‘Every algorithm has a learning aspect in it and it then depends on the amount of data you have. The emergence of deep learning has broadened the continuum of solutions, where at one end there is enough data to let the machine do the learning, at the other, where there is less data, the scientist guides the teaching phase.’

Lavi went on to say that machine learning is not new, but that tasks requiring artificial intelligence are becoming more common, especially as the available computing power increases. ‘There is now a vision component in almost any application you can think of,’ he noted. ‘These are exciting times, opening up a lot of opportunities and markets for us.’

One of the company’s current projects involves a learning-based smoke alert system, using several sources of visible and non-visible light. False alarms are reduced by training the machine to recognise the difference between actual danger situations and false positives. In another example, an inspection line is assembled to map the density of active material in plants. A sophisticated filter highlights hot spots on the plants, to allow for accurate extraction of the metric.

Lavi said that the growing use of deep learning requires computer vision engineers to learn new vision analysis methods, but he considers this a minor problem. ‘A deep learning algorithm follows an optimisation scheme, and optimisation is part of the traditional set of tools. It’s only slightly different from the thinking vision experts are used to. Almost every algorithm converges into some kind of optimisation.

‘Machine learning is not new. Considering all the readily available deep learning libraries, it’s just another tool in your toolbox.’

Volume Elements is applying 3D data to solve problems to a much greater extent than in the past, according to Lavi, even in projects that didn’t originally use 3D imaging. ‘We find the adoption and the will to use 3D schemes more and more common,’ he said. The company extracts image data from both 2D and 3D cameras, and fuses together information from different sources, such as radar, x-ray or infrared imaging.

Lavi said that industrial imaging remains an important market for the company, but it’s also seeing great interest in aerial and drone imagery, where he hopes that Volume Elements’ experience in 3D, along with tracking, detection and classification algorithms, could contribute a lot to these sorts of applications.