Matrox AltiZ high-fidelity 3D profile sensor powers TUNASCAN vision system, sorting up to 20 tonnes of tuna per hour with accuracy rates approaching 100%

Headquartered in Spain, Marexi Marine Technology Co. has been a marine technology leader for more than 15 years. They develop optical scanning systems for marine species for fishing, canning and aquaculture sectors. Their TUNASCAN® system is Marexi’s most state-of-the-art machine, a high-speed, high-throughput vision system that scans and classifies tuna by species, size and quality.

Visual classification of fish is challenging, especially once frozen. Differences between species become practically impossible to discern reliably without exhaustive testing. Using cutting-edge 3D profile sensors along with machine-learning algorithms, TUNASCAN properly classifies and sorts tuna with accuracy rates of more than 95%.

‘We are always seeking ways to further enhance our solutions,’ notes Pau Sánchez Carratalá, vision and robotics engineer at Marexi. ‘In the interest of improving the classification algorithms used by TUNASCAN, we overhauled the entire acquisition system with the support of Matrox® Imaging and Grupo Alava.’

Tuna are scanned by two Matrox AltiZ before being classified; 3D classification results and location data is sent to the sorting section. Credit: Matrox Imaging

Each tuna is automatically sorted into its appropriate container. Credit: Matrox Imaging

Just keep scanning

TUNASCAN is a major fixture of Marexi’s marine technology offerings; this patented two-channel vision system can process up to 20 tonnes of frozen tuna per hour. From the reception hopper, frozen tuna are fed into and pass through the scanning section, where two Matrox AltiZ sensors perform a 3D scan and a computer classifies each tuna individually. Classification results and location data are sent to the sorting system, where each tuna is sorted into its appropriate container.

Clear fishy fishy

Upgrades to the TUNASCAN project centered upon Matrox AltiZ 3D profile sensors. Sánchez Carratalá notes: ‘We needed a reliable way to obtain 3D point clouds from objects moving at a fairly fast speed. The application also must deal with point-cloud noise and dirtiness from physical operation of the machine. In the past we used separate cameras and lasers for obtaining 3D data. Matrox AltiZ allows us to integrate these elements into a single sensor that provides exceptional robustness to the application.’

TUNASCAN employs machine learning to accurately classify frozen tuna based on features extracted from the point-cloud representation and calculated weight. Matrox Capture Works – the interactive set-up utility for Matrox AltiZ – was used to configure the sensor and provide the code snippet for the acquisition portion of the actual application.

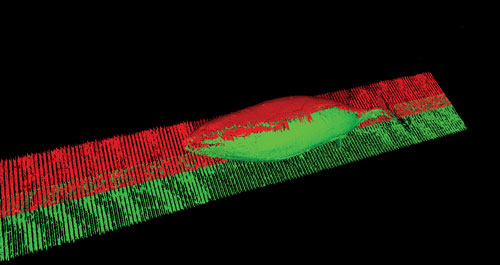

In the TUNASCAN system, the 3D devices are set to generate a point cloud. Laser lines trace the contours of the fish. Embedded algorithms then produce a point cloud, which is stitched together to create a complete 3D rendering of the tuna. The algorithm ensures greater control over invalid data, resulting in more robust 3D reproductions.

TUNASCAN also includes ultrasonic sensors that trigger 3D capture only when there is a fish available to scan. Special low-temperature infrared sensors are responsible for monitoring the temperature of each fish and assuring the proper behaviour of the system.

Fishing for results

Operator interaction with the system is minimal. In addition to sorting by species, the same species of tuna can be further sorted by weight. Every incoming fish is sorted into the selected categories by container. TUNASCAN manages multiple containers, automatically assigning a new container for output while the full container is being replaced, ensuring the system remains in continuous operation.

TUNASCAN systems are deployed in harsh environments and operate continuously, leaving very little opportunity for maintenance or calibration. ‘One of our installations has been working up to 20 hours a day, six days a week for almost three years, with barely any maintenance required,’ Sánchez Carratalá smiles. ‘All that, and with accuracy rates approaching 100%! Our clients could not be more pleased.’

An on-screen rendition of the 3D point cloud generated by the two Matrox AltiZ. Credit: Matrox Imaging

In the swim of things

As part of Marexi’s commitment to continuous improvement of their products, TUNASCAN has been regularly improved and optimised. ‘We faced some challenges at the start, mainly because it is a very complex and disruptive system, and we needed to guarantee its efficacy,’ Sánchez Carratalá reports. ‘We are happy with the assistance offered by Matrox Imaging’s technical support team, as well as the help received from Grupo Alava.’

Building on the success of the TUNASCAN upgrade, Marexi is currently working on a different project for the fish industry that also integrates a Matrox AltiZ, along with Matrox Imaging Library (MIL) X software.

Marexi reports that their current clients are very satisfied with TUNASCAN and the value it provides their businesses. ‘Our TUNASCAN application leverages the strengths of a Matrox AltiZ-based system,’ Sánchez Carratalá concludes. ‘Not only do the sensors deliver very accurate 3D data at really high conveyor speeds while dealing with a challenging product like frozen tuna, but the Matrox AltiZ functions optimally in extremely harsh environments and works for long periods of time without maintenance.’