Imaging firm Scorpion Vision is doing its bit to make sure supermarket shelves are stocked with items including tea, flatbreads, and sprouts.

Managing director Paul Wilson wrote in a LinkedIn post that the company had had an 'urgent call from a major tea producer'. A system Scorpion Vision had installed six years ago had failed.

Scorpion Vision's system uses a 3D camera to locate sacks of tea on a pallet. The camera locates the position and pose of each sack in space, and then sends the picking coordinates to a robot for automated handling.

The engineers at Scorpion Vision were able to log on and fix the problem remotely, thereby ensuring tea will continue to be delivered to supermarkets.

UK supermarkets are still struggling to stock certain items of food, although they have now lifted restrictions on some of their products that were imposed after stockpiling earlier in the month.

The firm's 3D vision technology is also used to process sprouts, which are located by the 3D camera, picked by a robot and trimmed by a waterknife. Wilson said the technology had processed 21 million sprouts to date.

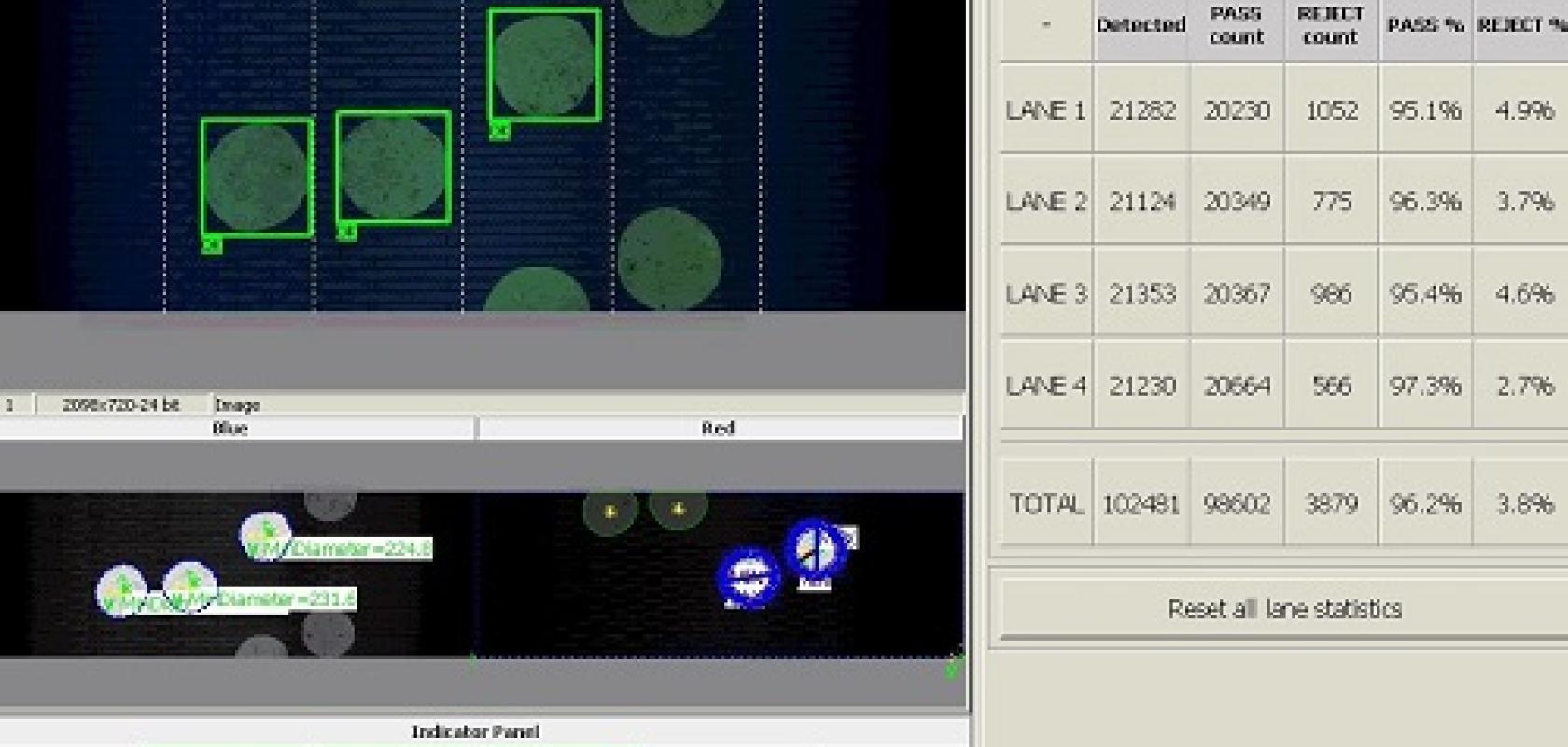

A similar technology is installed on a tortilla flatbread production line; the 3D imaging system is able to inspect at a rate of up to 45,000 flatbreads per hour. The camera locates each flatbread and measures it, looking for torn, deformed, burnt through the colour, or too large or too small products.

When it identifies any of these conditions, the vision system sends a signal to a series of pneumatic ejectors and the flawed product is individually removed using air jets.