In 2018, the USA grew 392.5 million tonnes of maize, roughly a third of the world’s maize production. A lot is used for animal feed, some for human consumption, and now, increasingly, much is being turned into ethanol for biofuels.

The milling process – to grind maize into different products – is complex, industrial in scale, and finely tuned to maximise the yield produced from each tonne of maize. An average mill in the US can reach a throughput of 1,000 tonnes of maize per day, Juste Hahne, product manager at Swiss firm Bühler, told Imaging and Machine Vision Europe.

Bühler builds machines to sort and process maize, relying on various optical sensing methods to do so. About 80 per cent of Bühler’s turnover is related to food and grain processing, maize being just one crop with which it works. Two out of three wheat grains are processed on Bühler equipment, as is 75 per cent of the world’s barley malt. Grain milling is one of Bühler’s traditional markets, but it also makes machines for processing rice, pasta, chocolate, nuts, and many other foods.

Some of the optical sensing techniques used onboard Bühler sorters and in-line sensor systems include: NIR sensing and spectroscopy, to determine chemical composition such as moisture or protein content; inspection and optical monitoring, to find and remove contaminants such as foreign materials; and also an optical measurement of granulation, to measure how coarse or fine grains or powders are.

Granulation of ground maize, be that flour or grits, is an important metric for mills, because their customers’ processes are strictly set up for an exact particle size of raw material. The mill’s customer will therefore only accept a certain degree of granulation. ‘If a mill doesn’t know the quality of its product it is lost,’ said Hahne. A rejected batch could be a loss of $10,000 in raw material, just because the mill didn’t meet the quality requirements.

In terms of grits, which are particles of endosperm used in snacks and breakfast cereals, a mill might have an output of 100 tonnes a day of flaking grits – the larger particles – and 500 tonnes a day of snack grits, a finer material sent to snacking companies. Snack grits, as well as being much finer than flaking grits, also might need different fat and moisture content.

By using optical techniques during the process of converting grain to grits, Bühler’s systems can optimise the yield of maize grits by 0.3 per cent. This, according to Hahne, can lead to additional earnings for the mill of $200,000 a year. ‘This is where we can really convince our customers why they need our technologies,’ Hahne said. In addition, since Bühler’s sensors work online during the process, the mill can save an extra $25,000 a year because it doesn’t have to run as many offline quality control tests on the product.

Bühler’s online Particle Size Measurement Unit is able to measure granulation optically. It uses a camera with a strobed LED to measure the shape and size of coarse particles, together with laser diffraction to detect fine particles. The output of these two sensors gives a particle size distribution between 10µm and 5,000µm. This range covers most products in grain processing, Hahne said. The company’s NIR Multi Online Analyser monitors the fat content of grits using near infrared spectroscopy.

Turning to wheat, installing a Bühler optical sorting platform can give around 0.8 per cent improvement in yield compared to using mechanical cleaning. When that is applied to 80,000 tonnes per year, it adds up to €125,000 of added saving for the customer.

‘A single grain of wheat has very little value, but when you’re talking about millions of tonnes, even the smallest improvement has an enormous knock-on effect,’ said Dr Tim Kelf, head of sensor development at Bühler. ‘When we’re talking about the 1 to 2 per cent improvement level that we can squeeze out through these optical techniques, that’s enormous for our customers.’

All in the delivery

A normal Bühler line will process 10, 20 or even 100 tonnes per hour, and that could be running 24 hours a day. ‘We’re talking about millions of objects per second, and all of them have to go through the imaging area,’ said Kelf. Ideally, all these particles need to be separated to make life easier from an imaging perspective, although the algorithms are able to extract information from the images even if particles are touching.

‘In order to present grains to an optical sensor it’s important to understand the physics of it all,’ said Kelf. ‘You need to make sure grains aren’t bouncing, while at the same time the flow of grain needs to be accelerated to 4m/s because otherwise you don’t get the capacity.’

Some products like chickpeas will bounce, whereas almonds will bounce less. Some grains roll a lot, some products are sticky. ‘It’s understanding the properties of the grain and the material properties of the chute, along with the chute’s geometry, to create a stable feed,’ Kelf said. ‘There’s no one solution. For frozen foods you’d use a very different system than you would for rice or nuts.’

As with many imaging techniques a lot depends on lighting. Firstly, the systems require very flat illumination profiles. Brightness has to be homogeneous to minimise the amount of variability in the image, and the angle of light has to be the same to remove any shadowing, Kelf said.

The light has to be tailored to the right application, whether that’s using colour or white LEDs, or UV LEDs for fluorescence imaging.

It is then a matter of trying to balance all these things, while keeping the light source in a sensible footprint, and also making it hygienic. There are constraints on temperature emitted by lights, and not having areas where dirt can accumulate. In addition, the machines can run 24 hours a day. ‘You need to have as much efficiency as you can in terms of uptime, while making sure the customer gets the most benefit from these systems,’ Kelf said. In the last few years Bühler has launched its Xenon lighting solution to boost the lifetime of incandescent illumination and reduce machine downtime.

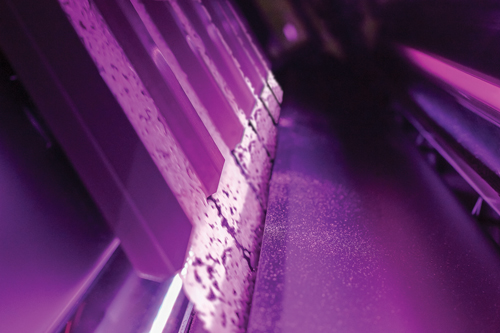

Rice sorting on the Sortex S UltraVision involves identifying very subtle yellow or grey grains. Credit: Bühler

Bühler uses two overarching lighting solutions: either many low-power white LEDs, or a small number of high-spectral purity LEDs. Spectral purity is less important when using many white LEDs, as they’ll all marry together, Kelf said. ‘At the high end, certainly for sorting rice, then you’d want to use a small number of LEDs with high spectral purity,’ he added. Rice sorting involves identifying very subtle yellow or grey grains, which requires exact colour imaging.

Bühler has just released its Sortex S CrystalVision system for sorting rice, which can remove colour defects and foreign materials, including glass, at 18 tonnes per hour. ‘To spot glass in rice comes down to knowing the illumination properties and what to look for in the image,’ Kelf said.

Food security

Maize production is concentrated in four countries: USA, China, Brazil and Argentina, which grow more than two thirds of the world’s maize. In a study published in 2018 in PNAS (115 (26) 6644-6649), the authors projected that mean total production of maize would decline by 18 per cent in the United States with 2°C of global warming. Wheat yields are also expected to decrease by six per cent for every 1°C global temperature rise, Dr Ian Roberts, CTO of Bühler, said during a virtual press conference the firm held to mark what would have been the Interpack trade fair.

Bühler has pledged to reduce waste, energy, and water in its customers’ value chains by 50 per cent, and is rolling out new technology and processes to help meet this target by 2025.

‘Estimates suggest one third of all food grown on the planet is lost,’ Dr Matthias Graeber, head of data science at Bühler, told Imaging and Machine Vision Europe. ‘At the same time, one third of all energy goes into food production. That means around 10 per cent of all energy is lost – a clear opportunity to act. We really try to minimise losses, and often that goes together with financial savings for our customers. It is good for our customers, but it’s also good for the environment – if we maximise the yield of flour that can be produced from one tonne of wheat, we’re more efficient with the raw material. Any small improvement we can achieve can have a massive effect globally.’

Bühler is also working with Microsoft to develop its LumoVision optical sorting machine, designed to spot maize contaminated with aflatoxin from fungal mould. Aflatoxin is a carcinogenic mycotoxin that causes 155,000 cases of liver cancer per year in developing countries, and contributes to stunting the growth of millions of children. The toxin is not destroyed by heat, so cooking doesn’t make it safe, and contaminated maize can’t be detected under visible light. However, the toxin does fluoresce green or yellow under UV light. LumoVision uses UV lights to illuminate maize grains flowing down a chute at 3.5m/s; cameras detect any fluorescence and air jets blow out the contaminated grains. In this way the system can process 10 to 15 tonnes of maize per hour; it can eliminate 90 per cent of contaminated maize with a yield loss of less than 5 per cent.

The challenge with fluorescence imaging, Kelf said, is that it requires much higher power density from the lights, and all the LED profiles have to be stable and flat. Fluorescence as a biological process is only about one per cent efficient, so requires 100 times more light than imaging techniques based on reflection. ‘Food safety is one of the structural pillars of Bühler,’ said Kelf. Along with tackling aflatoxin in maize, Bühler has built its Sortex A machine that can reduce vomitoxin in wheat. The system can remove 50 per cent or more of vomitoxin with only a 10 per cent loss of product.

Bühler’s NIR Multi Online Analyser monitors moisture, protein and gluten in grains and flours, as well as ash content, water absorption and starch damage. Credit: Bühler

‘This can turn a harvest from being unfit for human consumption to one that is safe to eat,’ Kelf said. ‘That can have an enormous benefit, not only to the yield the customer gets because it’s gone from effectively nothing to 90 per cent of the total, but it increases the amount of food for the planet, which is good for everyone. It also makes everything we’re eating safer. Making sure the food grown is processed to a high degree in terms of food safety and food quality benefits everyone.’

The system identifies wheat grains contaminated with vomitoxin based on a spectral signature. It uses a number of specific wavelengths in the infrared.

Advanced sensing

Bühler has also developed an online Colour and Specks Measurement Unit, which includes a digital camera with built-in optical reference tiles. It measures the colour of flour or semolina in the CIELAB colour space that corresponds to the human eye’s response to colour. A traditional approach to checking the quality of flour or semolina would be for the head miller to inspect the product in the palm of his hand. The camera is designed to mimic what the miller would see.

The unit gives a colour measurement in real-time as the product flows past. The camera can also count and classify unwanted black or brown specks – 80µm or larger – in the flour and semolina, which indicates processing deviations. The information is then used by the miller to adjust the process to meet the required specification, Hahne explained. A quality specification may allow a maximum of 25 black specks per squared decimetre for high-quality semolina for pasta production.

‘Bühler is always looking for incremental improvements through R&D, either reducing cost or improving quality,’ Kelf said. ‘Can you improve the image quality with a lens without adding too much to the cost, for example.’

Looking further ahead, the company is investigating ways of using near-infrared spectroscopy to measure and sort single grains, according to properties such as protein content or moisture, but doing so at high industrial capacities. ‘That’s an exciting prospect for the future,’ Kelf said.

What to make of a round swede

Imaging firm Scorpion Vision is making sure supermarket shelves are stocked with well-trimmed swedes and leeks, while at the same time reducing food waste in the supply chain.

The company’s Jana Lambrecht described two installations that were up and running as part of UKIVA’s technology hub, the virtual version of the association’s machine vision conference. All the presentations in the hub remain live and free to view.

Both systems use stereovision to guide a knife – mechanical or water jet – to trim the top and bottom of swedes and leeks at a rate of one vegetable per second.

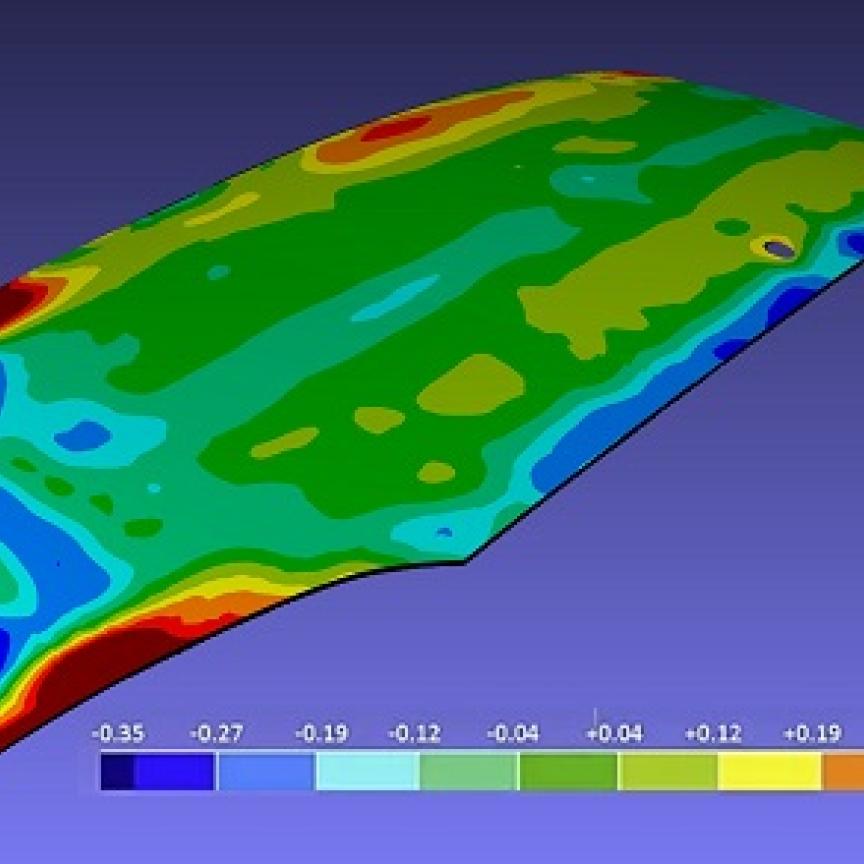

The swede trimming system uses two area scan colour cameras imaging in white light. The stereovision set-up gives a height map and contour of each swede. From this, the system finds the centre of the swede and then scans across its length in 5mm increments, making a width measurement at each stage. Once the width falls below a certain threshold the information is sent to a control unit to tell the system where to position the cuts.

Lambrecht said that the only problem the system encountered was when the swede was close to being perfectly round, because it’s then difficult to pinpoint an exact place to make the cut.

Leeks are trimmed with a water jet, cutting away leaves at the top, as well as the roots. The leeks are presented individually to the camera system in single pockets. The system uses three methods to determine a cut position, the best one of which is decided according to confidence values. One method is to use the difference in light intensities between the leek body and the root – the body is bright while the root is darker – and set thresholds for where to place the cut. There is also a 3D model, as well as a contour model of the leek, from which the indent between body and root can be seen.

The leek trimming system had to contend with steam from the water jet misting up the camera housing, as well as stray leaves obscuring the image.

Paul Wilson, managing director of Scorpion Vision, told Imaging and Machine Vision Europe: ‘We primarily use stereovision as it gives us the opportunity to look at something in 2D as well as in 3D, and there are advantages to using both image sets.

‘In terms of productivity gains, we aim to achieve 100 per cent image analyses with a valid output,’ he continued. ‘Of course, sometimes a product may not be properly presented for the cutting device, but nevertheless we will still attempt to make a sensible decision based on what the vision system sees. Quite often the limitation with these machines is the freedom of movement of the cutter if it is driven by servos – which is why the use of a robot can be better, as it can offer six degrees of freedom, which is of course the benefit of a true 3D vision system.’

By automating the process of trimming vegetables, such systems can reduce waste by making precise cuts, and also deliver food to supermarkets that meets quality requirements and that won’t be wasted because it’s left unsold.

Wilson commented that food production projects Scorpion Vision is involved with are continuing during lockdown, but that social distancing is causing some practical problems. He said: ‘There are definitely more discussions around automation. I think there was always a high level of interest, but implementing something is another story. I think there will be a rapid growth in automation for food production once we all get to grips with our new normal.’

Lambrecht said that there are many more applications where vision can be used to process fruit and vegetables. She said that the development and improvement of neural networks will make a big difference, especially for processing vegetables like broccoli, cauliflower and mushrooms that are more difficult to automate.

‘We see major benefits to combining neural networks with 3D image processing,’ Wilson said. ‘There are lots of areas where this is really good for us and many not so obvious benefits which will have a real impact. I think food production is going to be one of the biggest winners in this regard.’

There are also advances being made in imaging outside of the visible spectrum. Mike Grodzki, a product manager at Teledyne Dalsa, said the firm has had customers in food production asking for SWIR cameras for a while for detecting foreign contaminants in food. Teledyne Dalsa now supplies its Linea SWIR InGaAs line scan camera. ‘Sticks and stones might be difficult to visibly distinguish from raisins, for example, when they’re flying down a chute. In the visible spectrum they might all just be brown, but not so in the SWIR,’ Grodzki said. ‘SWIR cameras are also great for detecting bruising in fruit. Those ugly, bruised fruits aren’t wasted – they get used for things like jams, and preserves, or they get chopped up and sold in frozen packs of fruit.’

There are also vision systems employed in packing food for supermarkets. The UK supermarket Morrison’s installed two Brillopak robotic potato loading cells at its fresh produce depot in Rushden, Northamptonshire. The two UniPaker robot cells can load 75 packs of potatoes per minute into crates ready for distribution. Vision is used to identify the location of each pack for the robot arms to pick them up.

‘Vision is a strategic focus for Brillopak,’ the company’s director, David Jahn, told Imaging and Machine Vision Europe. Brillopak has now developed its own vision system and is involved in a number of development projects using vision and robotics.

The firm also has a new QA vision system to support its UniPaker robotic apple packing solution. The vision system identifies and rejects packs of apples containing cut apples, or those with the incorrect number of apples. It also reads information like the use-by date. Brillopak expects to roll out this system across all its sectors shortly, Jahn said.