Wind turbine blade manufacturing is improved with robotics

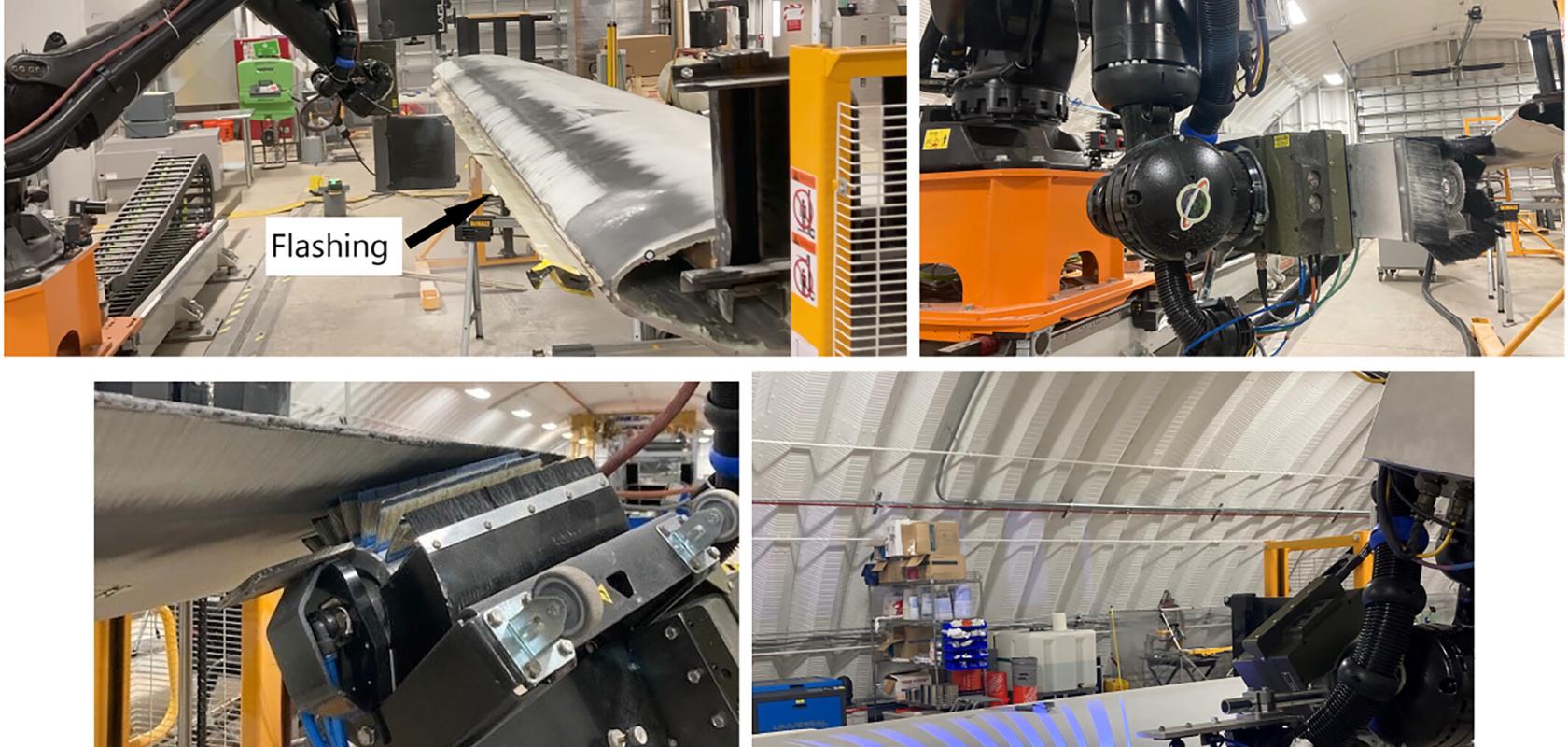

clockwise l-r: Robot with band saw attachment and 5m test blade section, Pushcorp grinding tool with custom dust collection shroud, Zivid II structured light camera and Tyrolit sanding tool. Images: Hunter Huth, NREL

Research conducted by the US Department of Energy’s National Renewable Energy Laboratory (NREL) has found that robotic assistance can improve the production process of wind turbine blades, increasing both the consistency of the finished products and the safety of the working conditions.

Register for FREE to keep reading

Join 10,000+ vision professionals driving innovation in automation, AI and imaging with:

- Expert insights on vision, robotics, AI & embedded tech

- Newsletters and features covering the full imaging landscape

- Visionaries series: leadership strategies in imaging

- Free panels on smart manufacturing & autonomy

- White Papers & updates for smarter integration

Sign up now

Already a member? Log in here

Your data is protected under our privacy policy.