A new AI-driven, 2D vision smart camera was launched by SICK at the UKIVA Machine Vision Conference show this week, harnessing the power of NOVA, the firm’s common development platform.

Launched at the UKIVA Machine Vision Conference & Exhibition this week, SICK’s Inspector83x 2D AI smart camera is now the fastest option available on the company’s wide-ranging NOVA platform. With a range of 2D and 3D machine vision products available on the platform, tailored solutions to unique challenges in automated inspection and measurement are now open to users.

A build-your-own machine vision system

NOVA is a scalable software platform for users to add, combine and customise machine vision tools for their own specifications and applications. "With a user-friendly web interface and AI capabilities," suggests SICK, "the simplicity of the system enables anyone, including those without expert machine vision knowledge, to build challenging machine vision applications."

Recent updates to the evolving system include tools and features such as suppress edge artefacts in AI anomaly detection, hardware acceleration to reduce the analysis time of the AI classification tool, 3D box detection and new list functions in the Expression tool. The software platform aims to make complex machine vision tasks more easily achievable by teaching its users with examples, instead of using manual rule settings.

Applications for a more flexible machine vision system

“The potential applications for SICK’s NOVA-powered technology and deep learning are limitless,” says SICK, “with existing applications ranging from identifying the presence of transparent objects in manufacturing and ensuring items are placed accurately in food packaging, to speeding up assembly processes and ensuring consistent quality in fish processing.”

“The potential of NOVA-empowered machine vision is vast,” said Nathaniel Hofmann, SICK’s product manager of machine vision and measurement for the UK market, but the “real value lies in our ability to offer full-spectrum machine vision solutions. We’ve got a comprehensive hardware and software range, [so] tell us what you need and we will use our machine vision expertise to make it a reality.”

The importance of an out-of-the-box solution

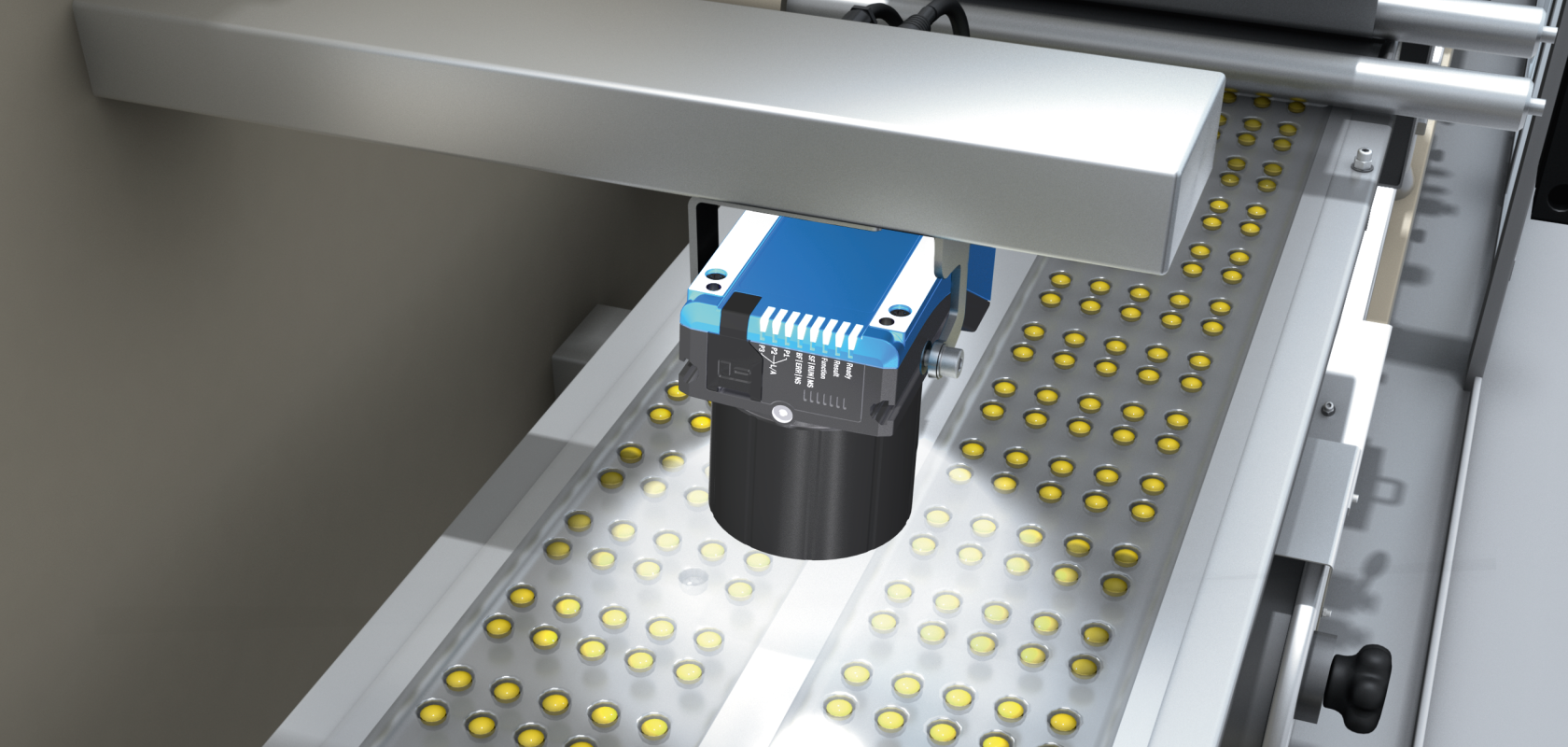

Making “the most challenging machine vision tasks possible with high accuracy and high-speed data transfer over industrial networks,” said SICK, the Inspector83x features 5MP resolution, a powerful quad-core CPU and built-in illumination, with the ability to process AI inspections directly on the device at high speed, with no external machine control required.

A teach-in capability allows the camera to be efficiently used by non-specialists at any time, while still providing powerful, high-precision AI inspections without a reduction in production speed. Meanwhile, "after showing the camera as few as five examples," says SICK, "it can begin to perform complex inspections of medium to large scenes, of products with unpredictable features and verify assembly systems."

“The Inspector83x is the ultimate quality control tool,” said Viktor Smedby, SICK product manager and lead architect of the Inspector83x: “We’ve designed it to make quality control user-friendly and efficient, offering the perfect solution to perform demanding inspection tasks at high process speeds, for applications like quality assurance, detection and sorting tasks.”