The latest image processing products and solutions in 2025

Image processing is the manipulation of digital images to enhance or extract useful informationTitima (Credit: Ongkantong/Shutterstock.com)

Image processing is crucial to today's machine vision systems, allowing computers to extract meaningful information from visual data.

What is image processing?

Image processing is the manipulation of digital images through computational algorithms to enhance or extract useful information from them. It can transform an input image into either an improved image or extracting specific data.

It involves a series of operations applied to digital images represented as arrays of pixel values. These operations modify, analyse or interpret the visual data for specific applications.

Euresys Deep Learning software tools

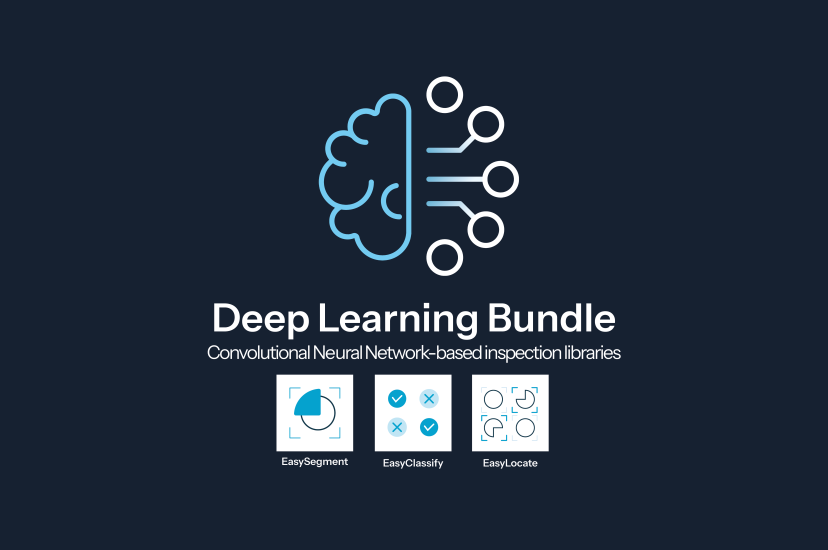

Euresys’ software tools address the various challenges of evaluating and prototyping Deep Learning based vision applications.

A bundle of Open eVision Deep Learning libraries offer multiple inspection functionalities based on Convolutional Neural Networks (CNNs). They are used to solve complex problems difficult to solve with so-called conventional computer vision algorithms.

EasyClassify to classify objects/images in categories and displaying the classification probability

EasySegment to perform defect detection and segmentation. It identifies parts that contain defects, and precisely pinpoints where they are in the image.

EasyLocate to localise, identify and count objects, products, or defects in the image.

Open eVision Deep Learning Studio is an application that assists the user during the creation of the dataset as well as the training and testing of the Deep Learning tools of Open eVision.

It allows you to test the Deep Learning libraries using your own images. No programming is required. Open eVision Deep Learning Studio is free and does not require any license.

SPONSORED BY

The process typically begins with image acquisition via sensors or cameras, converting optical information into digital signals. Pre-processing steps then enhance image quality through noise reduction, contrast adjustment and normalisation.

The techniques used can transform raw image data into actionable insights across multiple industries.

What are the core image processing techniques?

Modern vision systems begin with high-quality image acquisition using CMOS or CCD sensors, followed by pre-processing steps like noise reduction and contrast enhancement.

Image segmentation divides images into regions of interest, usually through thresholding or edge detection. Feature extraction then identifies distinctive characteristics through methods like SIFT, SURF or ORB.

Edge detection algorithms such as Sobel, Canny or Laplacian operators highlight boundaries between regions, often implemented on FPGAs for real-time performance.

What are the industrial applications?

Factory automation relies heavily on machine vision for quality control, with high-speed systems inspecting products at rates exceeding 1,000 parts-per-minute.

Bin-picking applications combine 3D imaging with sophisticated algorithms, while surface inspection systems detect defects down to micron levels using structured light techniques.

Image processing products on the market now

Imaging hardware

Basler provides industrial cameras offering exceptional price-performance ratio with high-speed GigE and USB3 interfaces. The company's ace, dart and boost series cater to diverse applications with frame rates up to 1,000 fps and resolutions reaching 24MP.

FLIR Systems specialises in thermal and multispectral imaging solutions with industry-leading uncooled microbolometer technology. The company's Blackfly and Oryx cameras integrate seamlessly with machine vision software whilst offering temperature measurement accuracy of ±2°C.

Sony Semiconductors develops CMOS sensors, featuring Pregius and Pregius S global shutter technology. Its sensors achieve quantum efficiency exceeding 80% and dark noise levels below 2e-, setting industry standards for sensitivity and dynamic range.

Teledyne DALSA provides premium line scan and area scan cameras featuring TurboDrive technology. Its Piranha and Linea series offer line rates up to 200 kHz, whilst its Genie Nano cameras provide cost-effective solutions for industrial inspection.

Software platforms

Cognex’s VisionPro suite is designed for factory automation and deep learning tools. The company's patented PatMax technology enables geometric pattern matching with sub-pixel accuracy regardless of part orientation, and its ViDi deep learning tools require minimal training samples.

Euresys specialises in image acquisition and processing with advanced frame grabbers and software libraries. Its Coaxlink frame grabbers support data rates up to 25Gb/s with CoaXPress 2.0 interfaces, whilst its Open eVision software suite provides optimised algorithms for surface inspection and metrology with execution times under 5 ms for standard operations.

MVTec’s HALCON library offers more than 2,000 operators covering all aspects of industrial image processing. Its hardware-accelerated matching technology achieves processing speeds up to 10 ms per image, with robust support for 3D point cloud processing and surface analysis.

Matrox Imaging offers Design Assistant and MIL libraries to help enable rapid development with flowchart-based programming environments. The company's SureDotOCR technology delivers unmatched reading accuracy for dot-matrix text, whilst its latest GPU acceleration provides 5x performance improvements.

The Vision Development Module from National Instruments integrates with LabVIEW for complete system development. Its hardware abstraction layer supports more than 7,500 camera models, and its FPGA-based acceleration delivers deterministic performance for time-critical applications.

Integrated solutions

Keyence provides all-in-one vision systems, featuring auto-focus capabilities and intuitive user interfaces. The company's CV-X series includes built-in lighting controllers and supports multi-camera setups with synchronisation timing down to microseconds for high-speed moving objects.

FH-series controllers from Omron can deliver real-time processing for production lines with advanced shape search capabilities. Its controllers can manage up to eight cameras simultaneously with parallel processing architecture, enabling inspection times under 20ms even for complex operations.

Sick provides a comprehensive range of 2D and 3D vision sensors with onboard processing for space-constrained environments. The company's SIM4000 Sensor Integration Machine consolidates data from multiple sensors, whilst its AppSpace platform allows custom application development.

Available from Datalogic are specialist barcode readers and vision systems, optimised for logistics applications. The company's Matrix series cameras achieve read rates exceeding 99.9% even on damaged codes, and its Impact software enables quick deployment without programming expertise.

AI and deep learning

Algolux offers computer vision for challenging lighting and weather conditions. Its Atlas camera calibration technology automatically optimises sensor parameters, whilst its CANA perception software maintains object detection performance even in rain, fog and darkness.

AImotive provides autonomous driving perception systems that leverage sensor fusion techniques. Its aiDrive stack processes multi-camera inputs in real-time with power consumption under 20W, enabling Level 2+ ADAS features on automotive-grade processors.

Available from DeepCognition is a no-code deep learning platform specifically designed for industrial inspection tasks. Its automated neural architecture search optimises model structures for specific applications, achieving accuracy improvements of 5-15% compared to standard architectures.

This is not an exhaustive list. If you provide products or solutions for image processing and would like your company to be included, please email editor.imaging@europascience.com.