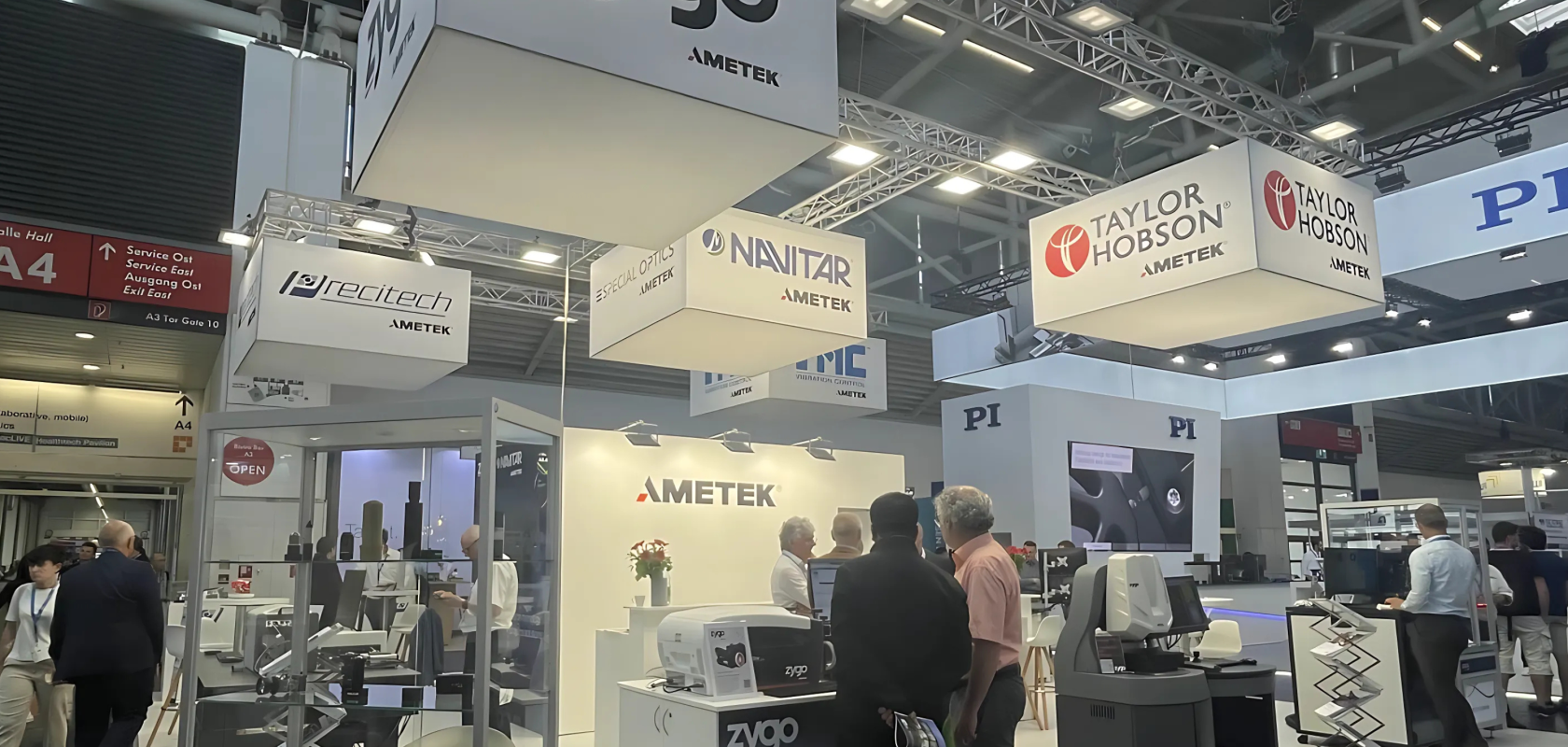

At Laser World of Photonics in Munich, Navitar's Patrick Buvé used the company's exhibition space to demonstrate why custom optical solutions are becoming increasingly critical for OEMs across diverse industries.

The International Sales Manager for Navitar, Special Optics and Pixelink, part of Zygo-Ametek , highlighted how the company's approach to bespoke lens design and active alignment technologies is opening new markets in Europe.

Showcasing bespoke solutions for advanced applications

"We don't show our off-the-shelf zoom range of products here," explains Buvé, standing beside an array of custom optical components. "What we're showcasing is our range of custom objectives for laser scientific and life science applications, – including non-magnetic objectives, laser beam expanders, scan lenses, and Pixelink cameras."

The company's differentiation lies not just in custom lens design, but in what Buvé describes as active alignment – a process where lenses are precisely aligned with camera sensors to create integrated modules. This capability has proven particularly valuable in autonomous vehicle applications, where Navitar designed lenses for a self-driving car project. The technology has more recently found new applications in defence-related projects where perfect optical-sensor matching is crucial.

One striking example on display is a projector system that demonstrates the company's range of capabilities. The housing contains a laser input, optical elements, and mirrors, while a DLPchip is used to project specific patterns onto surfaces. "This is something you can use, for instance, in 3D printing," notes Buvé, illustrating how custom optics are enabling new manufacturing technologies.

From prototype to manufacturable product

The journey for many OEMs often begins with internal experimentation, using off-the-shelf components.

"Quite a lot of them start by buying components and trying to put something together themselves, and then manage to get it working," says Buvé. "But then to make that into a manufacturable product is something else."

This is where Navitar's expertise becomes invaluable. The company can either start from a customer's existing design or completely redesign systems for manufacturability. "We know that if you do it like this, then you can achieve a yield of this much," explains Buvé, highlighting how design choices directly impact production efficiency and costs.

The scale of investment reflects the sophistication of these applications. Research institutes have paid up to $100,000 for individual objectives, with some of these custom lenses contributing to Nobel Prize-winning research. However, for commercial applications requiring hundreds of units annually, the economics change dramatically, making custom solutions viable for a broader range of OEMs.

Navitar's strategy at the trade show reflects the complex nature of their business model. While Buvé handles scheduled meetings with key customers, a colleague actively walks the exhibition floor searching for potential new OEMs among the exhibitors. "Rather than the end-user who just needs one solution, our customers are the exhibitors themselves – the companies that will integrate our optics into their systems."

As Buvé notes, “This isn't a transactional sale; it's a project that often involves a year of in-depth consultation with the customer.'" This emphasises how relationships and understanding specific applications drive the business rather than transactional sales.

Building European recognition for customisation

The European market presents particular opportunities for Navitar's customisation capabilities. "What is different between Navitar in the US and here is that perhaps companies here don’t take full advantage of the customisation part," notes Buvé. "We want to put that up front and say it's not only standard parts, but we have a team of people that can answer your questions for any custom project."

This positioning is strategic, as European customers often have specific requirements driven by local regulations, unique applications, or demanding performance specifications. The company's ability to provide fully custom-designed systems for military, scientific, life science, and medical applications positions it well for growth in these regulated markets.

The diversity of applications showcased at Munich – from autonomous vehicles to 3D printing, from defence systems to biomedical research – demonstrates how custom optics are becoming enabling technologies across multiple industries. As these sectors continue to evolve and demand increasingly sophisticated optical solutions, companies like Navitar that can bridge the gap between laboratory prototypes and manufacturable products are likely to find themselves in an increasingly strong position.

For Navitar, the Munich show represents more than just customer engagement – it's about establishing the company's European credentials as a partner capable of turning optical challenges into commercial opportunities. This strategic focus ensures that as European industries continue to push the boundaries of optical innovation, Navitar stands ready as a key enabler.