How pharmaceutical quality control is being enhanced with Edmund Optics’ 120i objectives

Inspections and quality controls play a crucial role in ensuring the quality and safety of pharmaceutical products. Today’s increasingly large-scale productions of pharmaceuticals combined with regulatory bodies’ strict controls have given rise to the need for 100% visual inspection of pharma products such as tablets, capsules, powders, vaccines and other liquid drugs. From R&D and production to product and quality control to packaging monitoring, machine vision is growing in popularity within the pharma industry as an automated step in the production chain of medicines.

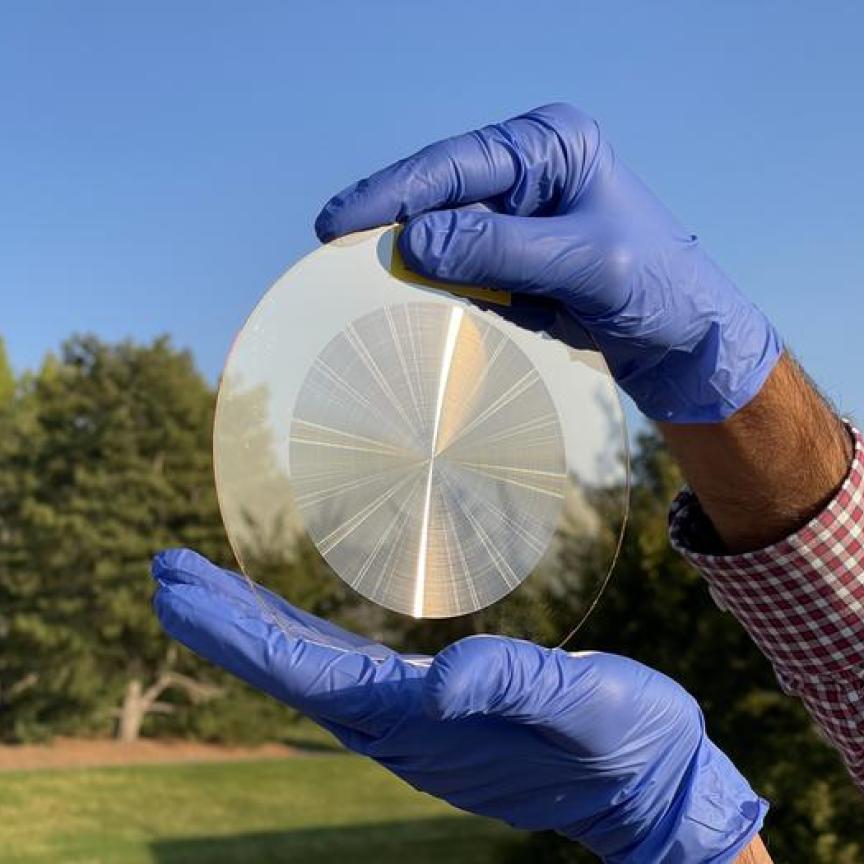

These machine vision systems rely on high-quality optics in order to provide detailed images for further image processing and defect detection. Edmund Optics’ TECHSPEC 120i Plan APO Infinity Corrected Objectives (120i), currently available in 5, 10, and 20X magnifications, are ideal for easy integration into imaging systems required for such applications.

Compact and lightweight

One notable advantage of the 120i objectives is their compact overall system length and lightweight construction, which facilitates seamless integration into various inspection devices. For applications such as identification or categorisation of tablets, especially where the tablet is to be inspected for surface irregularities or size, an array of two or more cameras is often used. Due to their compact format, the 120i offers a space-saving solution for set-ups with multiple camera systems as well as reducing the overall weight of the set-up.

They may also be easily integrated into other inspection devices since, due to their compact form, they are little affected by space constraints. Additionally, the 120i objectives are equipped with C-Mount threading, enabling effortless integration into a wide range of camera systems. With the

ability to effortlessly integrate into existing set-ups, these objectives provide flexibility

and adaptability to various inspection processes.

Precise colour rendering

To ensure a user is taking the correct drug, tablets and capsules are made to be easily distinguishable. In order to differentiate one drug from another, they may be different shapes, sizes or colours. Drug characterisation often involves recognising different drugs based on their colour.

Equally, colour variations or discolouration in pills may indicate defects. Errant pills on the production line of differing colours may also be identified for removal, and colour may also be used to gauge the content or concentration of a coloured drug within a tablet or capsule. For applications such as these, it is necessary to have a well-corrected objective in order to be able to properly distinguish colour differences. As Plan Apochromatic objectives, the 120i series are designed to offer chromatic correction for three colours: red, green, and blue, thus eliminating as much chromatic aberration as possible for precise colour rendering.

Meeting high demand

With an ageing population and rising demands for pharmaceuticals, production lines are working to create more output as fast as possible while still retaining the safety and quality standards set by governing bodies such as the Food Drug Administration (FDA) in the US, or the European Medicines Agency (EMA) in Europe. For example, for tablets, this may mean an inspection of the surface in order to check for misshapen surfaces or defects that may mean the optimal dosage for that unit has not

been achieved.

Larger sensors offer larger fields of view such that a larger portion of the tablet or a larger number of tablets may be inspected at any one time. Equally, in order to have 100% visual inspection on multiple such safety and quality parameters on a very large-throughput production line, it is important to have a high-performing optic in order to capture all the detail necessary for further image processing. For example, some tablets or capsules also have a small code or other identifier imprinted on their surface. Should this imprint be malformed or misprinted, it may mean that the identifier is not readable and thus the tablet may not be distinguishable, posing a safety risk for the user.

Capturing every detail with unmatched performance

Edmund Optics’ 120i objectives are specifically designed to work directly with a 1.1-inch sensor, featuring a field number of 17.6mm. This enables imaging systems to work with larger sensors and thus a larger field of view for higher throughput. The objectives also feature excellent performance across the width of the sensor, achieving image flatness across the field. This enables inspections of larger areas while still at full performance. With the ability to effortlessly integrate into existing set-ups, these objectives provide flexibility and adaptability to various inspection processes.

Edmund Optics, a leading manufacturer of optical components, has developed the 120i objectives in-house. With four imaging design centres and a dedicated team of optical and optomechanical designers, project managers, and manufacturing engineers, Edmund Optics ensures the highest quality standards throughout the development process. From initial design and prototyping to scale-up and volume production, the company’s expert team supports customers every step of the way, delivering innovative and award-winning imaging lenses designed for the most demanding and cutting-edge applications.