Data is now a fiercely guarded asset for most companies and, as the European General Data Protection Regulation (GDPR) comes into force, Framos’ Dr Christopher Scheubel discusses potential new business models based on 3D vision data, following a talk he gave at the Embedded Vision Summit in Santa Clara this week

A business model essentially dictates how an organisation creates value and delivers this value to its clients. Gaining a competitive edge from manufacturing industrial goods or raw materials is based on a specific technology or production process. Customers pay for a certain technology or goods; companies entering the market encounter hurdles in copying or improving upon the technology or product.

The world of data is different. Great databases are made while applying new technologies to data. Data can be the basis for building enhanced user experiences and it can create new business models with advantages for companies lasting many decades.

Competitive advantages based on data will be much more sustainable than competitive advantages based on technology or production processes. Currently, companies like Netflix, Spotify or LinkedIn achieve and maintain their edge through their user data.

Business models tapping into 3D

Depth information is created by different methods including laser triangulation, stereovision, multi-view, or time-of-flight. The current disruption is not the technology itself, but rather the economics of the technology.

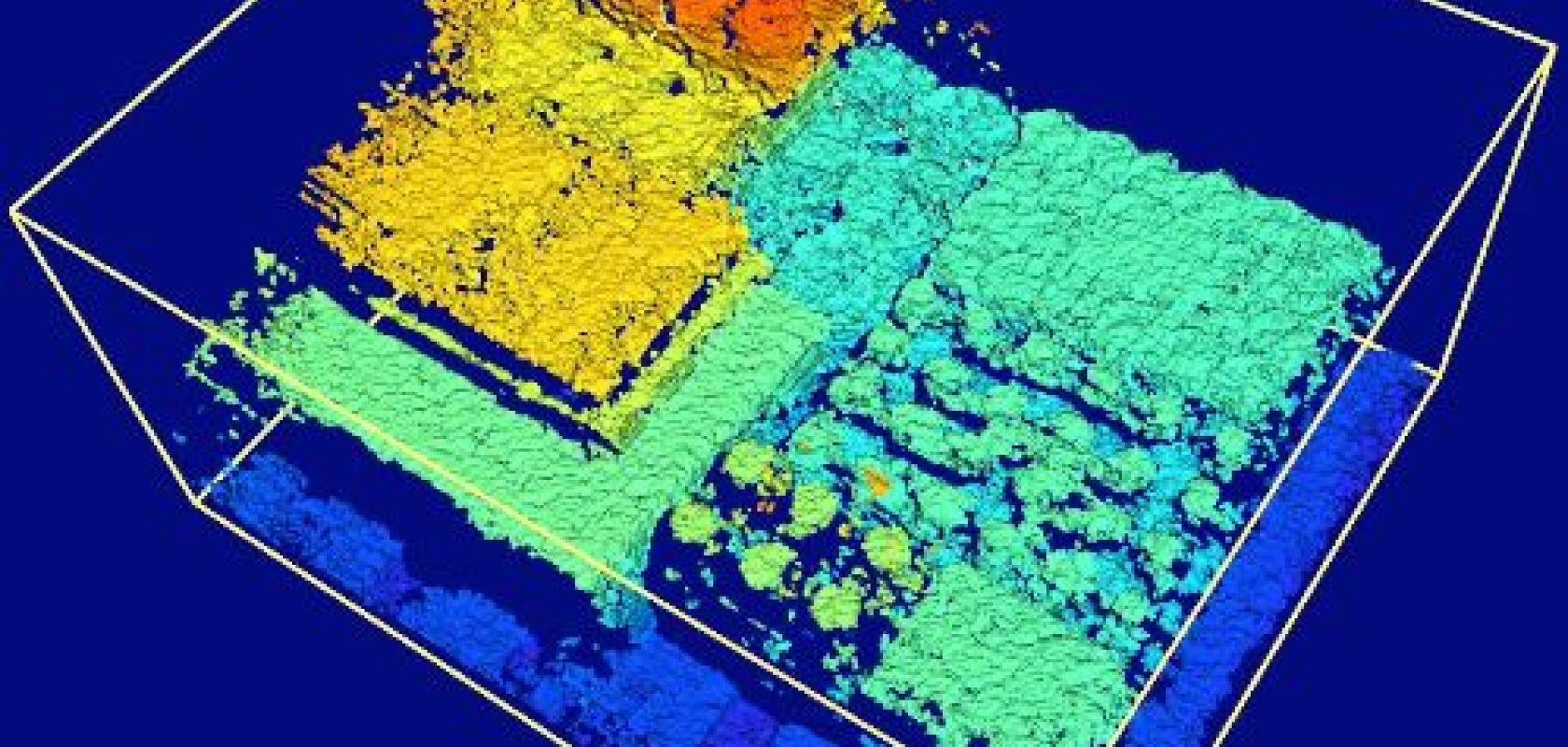

Raw 3D data in the form of depth maps, point clouds, and voxels can be employed in applications such as object recognition for security and surveillance, or situation awareness for autonomous vehicles. Yole Développement, a market research company, forecasts a compound annual growth rate of almost 40 per cent in the 3D vision market, most of which will come from the consumer sector like automotive, white goods, mobile phones, and home devices.

There is a huge potential for creating new business opportunities with 3D data, and more data-driven business models are likely be established in the near future. Data is a valuable commodity, but how can its potential be realised?

In a logistics project that Framos was involved in, a robotic system was devised to unload sea freight containers. The robots use both 2D and 3D vision to handle items in a container. In addition, semantic segmentation was used to find the edges between the boxes.

A 3D camera determines how the robot approaches and manipulates the item in the container, thereby creating a database about both the container and its contents. System performance based on this database increases tremendously, and virtually any item can be unloaded without error. In addition, reinforced learning is possible, as there is feedback about whether the unloading process worked adequately, or if there were problems.

Intel’s RealSense 3D camera is available through Framos

Different business models using this data are possible: the carrier could be charged for the way the container is packed, for example, and the degree of automation that can be applied to the unloading process. If there is enough perspective on containers, even a business model based on the amount and types of goods that flow through unloading facilities appears to be realistic. Therefore, information about which goods and where they are shipped can be applied to market-based pricing.

Another example is the 3D technology that self-driving cars, drones, and other types of robot rely on to navigate autonomously. Simultaneous localisation and mapping (SLAM), a methodology by which 3D maps enable autonomous vehicles to navigate within their environment, provides completely new business opportunities. The accumulated 3D data not only increases the robustness of the SLAM algorithm and the accuracy of the system, it is a valuable resource with which to create a competitive edge.

Three dimensional maps of the world – inside buildings and out – can be made instantly; they provide innovative opportunities for existing businesses. For example, some consumers still spend large sums of money on a robot vacuum cleaner. In the future, they could save money with leasing models that come with advertising. The intelligent and IoT networked vacuum cleaner would be able to identify the exact size of the apartment: the floor plan, the brands, the condition of the furniture, and individual furnishing styles. This data would allow conclusions to be drawn about the level of the owner’s income and, with the appropriate consent, provide personalised advertising.

A furniture store, for example, could send targeted advertising for a particular couch to potential customers, which matches the dimensions, style, and the price based on their lifestyle. These data-based models would favour this type of vacuum cleaner, because the manufacturer makes its profit using the sales data. In addition, it is conceivable that customers could lease these vacuum cleaners on a per-use basis and receive advertising accordingly. It is important to remember one hypothesis from last year’s Embedded Vision Summit: 3D maps of the world in the future will be much more valuable than Google Maps today.

Think data

Companies wanting to benefit from 3D vision and brainstorm ideas for future business opportunities have to think thoroughly about their processes and applications. Is there a way to enhance or enable the existing applications using 3D technology, with corresponding methods like SLAM or object recognition? This can be the premise for a powerful database with which to establish a competitive edge. Most likely, it will be the basis for AI, which uses large databases.

Managers should think about the kind of data that can be collected and how it can be used. These steps are the foundation from which to develop promising business models using 3D data, and maintain a competitive edge along with creating even more useful data.

Dr Christopher Scheubel is the head of IP and business development at Framos.