An innovative 3D vision system is being used to improve sorting accuracy and reduce manual handling of moulded door facings at the Irish facilities of building products company, Masonite. The system was required to identify the door facings based on the moulding design and surface texture. Two door facings are pressed side by side, with the different door pattern combinations produced from a large stock of single door facing dies. There are thousands of possible die combinations, so the sorting system was required to accommodate multiple die combinations and frequent die changes.

Masonite commissioned Alpha Vision Design, a specialist industrial machine vision company, to deliver an in-line automatic classification system. Robert Sadlier, senior controls engineer at Masonite Ireland, noted: 'Given the large number of possible die combinations, the large surface area and the relatively shallow moulding depth of the door facings, it was difficult to specify a suitable vision system to capture high quality, repeatable images and to accurately categorise the multitude of door facing combinations.'

At the beginning of the production run, the operator trains the system for the first set of facings using a simple training wizard. Subsequent facings would then be automatically inspected and classified. The vision system would communicate with the production line's control system, which would route the classified facing to the appropriate collection bay.

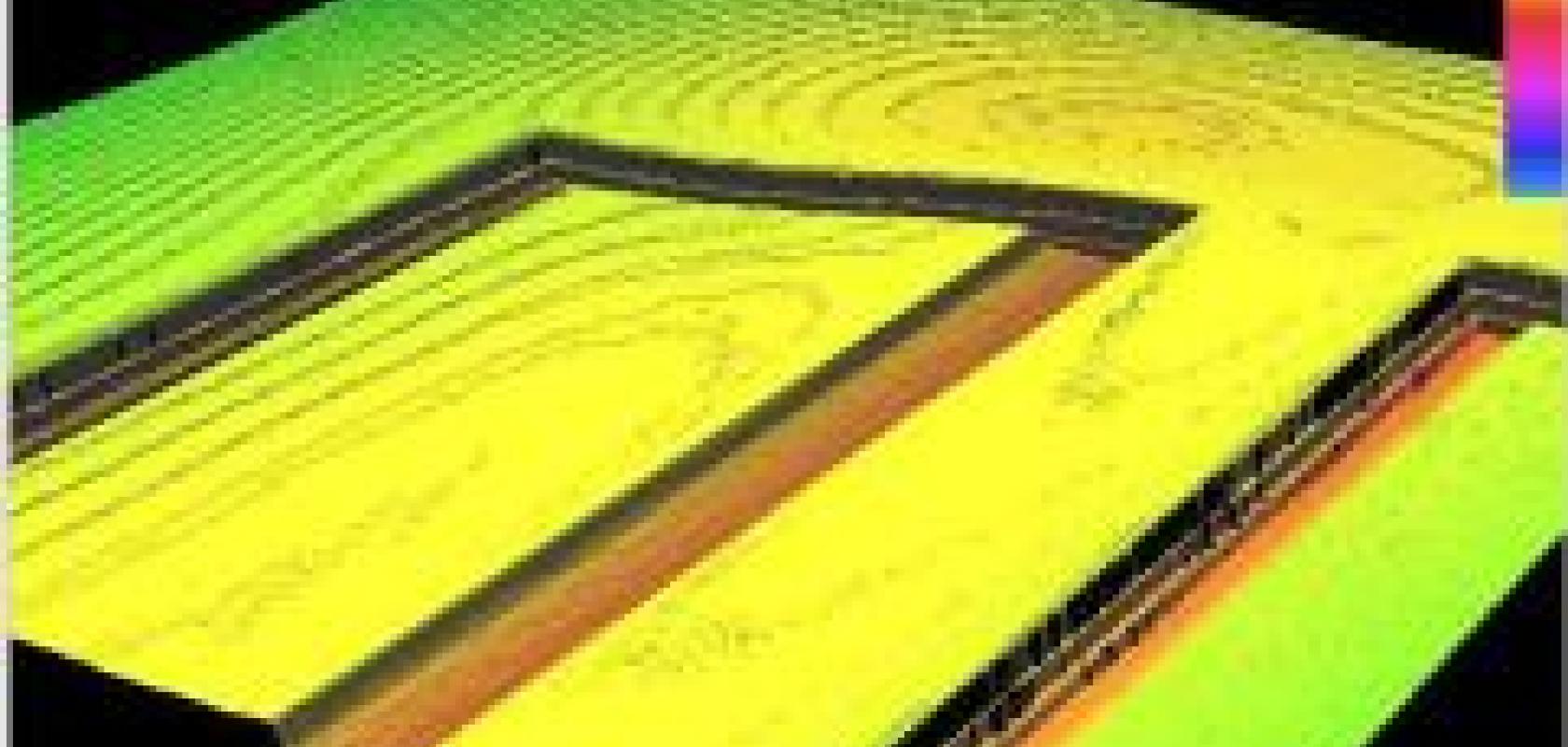

The system is designed to capture 3D data of the moulded door facing's patterns, using diode laser line generators and a line-scan 3D image acquisition camera. The height sensitive image data is transferred to the PC's frame grabber via a Camera Link interface to build and create a 2D height profile image of the double door facing being inspected. The image is then processed using VisionPro software from Cognex. The advanced PatMax tool provides the ability to perform unique geometric pattern matching and to classify shapes, even at low contrast, as encountered in this application.

Smart 2D vision cameras and halogen lighting are used to provide the required surface texture information, which is integrated into the vision system using digital input signals.

'The advanced functionality of the Cognex VisionPro software contributed significantly to the project's success, allowing the system to exceed the original user requirement specification, providing a sorting accuracy in excess of 99.97 per cent (i.e. fewer than 3 in 10,000 incorrectly classified),' said Sadlier. 'Manual re-sorting of product has virtually been eliminated, increasing yield, and allowing operations personnel to perform tasks that add value to the product.'