The Covid-19 pandemic has thrust the world of robotics into public consciousness. It has been reported in mainstream media that big-name brands – including American retailer, Walmart, and fast-food giant, McDonald’s – have been testing robots as cleaners, cooks and servers while human employees are unable to undertake the same duties because of social distancing.

Large warehouses, such as those operated by Amazon, have embraced robots to improve efficiency over the last few years, and the Covid-19 pandemic has heightened this trend. Now online retailers are looking to increase their use of robots for sorting, shipping and packing applications.

In healthcare, the pandemic has, naturally, put a lot of emphasis on the capacity for testing people – those thought to be infected, as well as healthcare workers and other key workers – to help stop the spread of the virus, and in testing laboratories robots can very much prove their worth. This was particularly evident in a recent installation at Aalborg University Hospital in Denmark.

The establishment is the largest hospital in the North Jutland region of Denmark, and it receives thousands of blood samples in its laboratory every day from physicians across the region. These samples need to be tested and sorted, which can be a time-consuming and monotonous manual process. Last year the hospital installed a robot handling system to automate parts of this work.

To provide some context, before the robot system was installed, the hospital’s laboratory staff would open transport boxes upon arrival, removing the blood samples and sorting them for further analysis. Because of the volume of boxes, some employees were known to suffer from tendon and muscle injuries as a result of the repetitive work.

Annebirthe Bo Hansen, department head at Aalborg University Hospital, explained: ‘We wanted to automate this process to ease the burden on our employees. Furthermore, we were looking for a solution to improve monitoring the quality and temperature of the blood samples.’

Automatic for the people

One of the companies instrumental in setting up the solution was LT Automation, which designed and implemented the system using two Kuka robots.

Anders Kjergaard Madsen, technical manager and owner of LT Automation, explained: ‘Approximately 3,000 blood samples are delivered to this department each day. These blood samples need to be sorted and analysed with different machines. What we have developed is a robotic solution to do this task.’

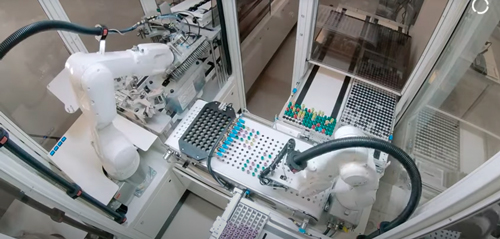

The robots sort samples and place them in a buffer. Credit: LT Automation

A conveyor belt now carries the transport boxes to the robots, shielded by Plexiglas screens. Software developer Intelligent Systems built the software that monitors the temperature of the blood samples during transportation.

The process begins as soon as the boxes enter the laboratory, where a Sick RFID logger detects whether the samples were kept at a constant 21°C during transport. Madsen continued: ‘When the boxes enter the room, the RFID scanner reads out the information… about the temperature and also [records] when it arrives.’

Object recognition

The system uses two Kuka robots: a small KR 3 and a medium-sized KR 10. Both of these models fall under Kuka’s KR Agilus series, which benefits from its VisionTech capabilities. These are particularly useful tools when it comes to 2D object recognition in quality control applications, thanks to the camera within the robot’s housing. The robots are able to pick up the transport boxes – which consist of an outer and an inner box – and then take these apart and open them.

The next step is to check that all of the samples are placed correctly. ‘We check this with a 3D camera,’ explained Madsen. The camera used here is Sick’s TriSpector1000.

This model was chosen for its reliability, providing accuracy even if there are variations in the part colour, position and height of an object. With time a key factor in sorting these samples, ease-of-use for the operator was important. In addition, factory calibrated data allows for a simplified set-up, as well as a reduction in time and effort. It also helps that the camera is a robust and waterproof model when being used in sometimes unpredictable medical environments.

After checking for placement with the 3D camera, it is the turn again of the robots, which pull out the samples and place them in a buffer. ‘This is where we can check the colour of the lid of the sample, according to type,’ Madsen explained, ‘and then sort them out into two different racks for further analysis.’

A 3D camera checks the samples are positioned correctly. Credit: LT Automation

In the past, the staff opened these boxes manually and pulled out the samples and closed the boxes again. ‘This is not a difficult task,’ Madsen said, ‘but it’s a very hard task on your wrists and on your hands, and caused a lot of injuries.’

The gift of time

Today, the university hospital benefits from the robot-based system with quality control checks, while also demonstrating how hospital workflows can be greatly simplified by automation. Specialist staff now have more time for patients – which is particularly advantageous in times of intensive stress or staff shortages, such as many hospitals are currently experiencing.

‘The idea actually came from this hospital,’ said Madsen. ‘It has a department for innovation and they had a competition where they pulled out some good ideas!’ The next step was finding the relevant companies to come and help develop the ideas.

The cell system is modular, so there is a module for handling the boxes, one for handling the racks, one for opening the boxes, and one for sorting the samples. ‘This is possible,’ said Madsen, ‘because we have the Kuka robots which we can fit directly on the modules, and the controller can be fitted within the cabinets. This means we can easily configure it to different customer requirements.’

The new system was initially tested in March 2019 and went into full operation in August. The lab technicians now have more time to analyse the blood samples, and, what’s more, the automated sorting and continuous temperature control in the transport box have reduced potential sources of error. ‘We are confident that this product can be used for a lot of hospitals around the world,’ concluded Madsen. ‘This could really make an impact.’