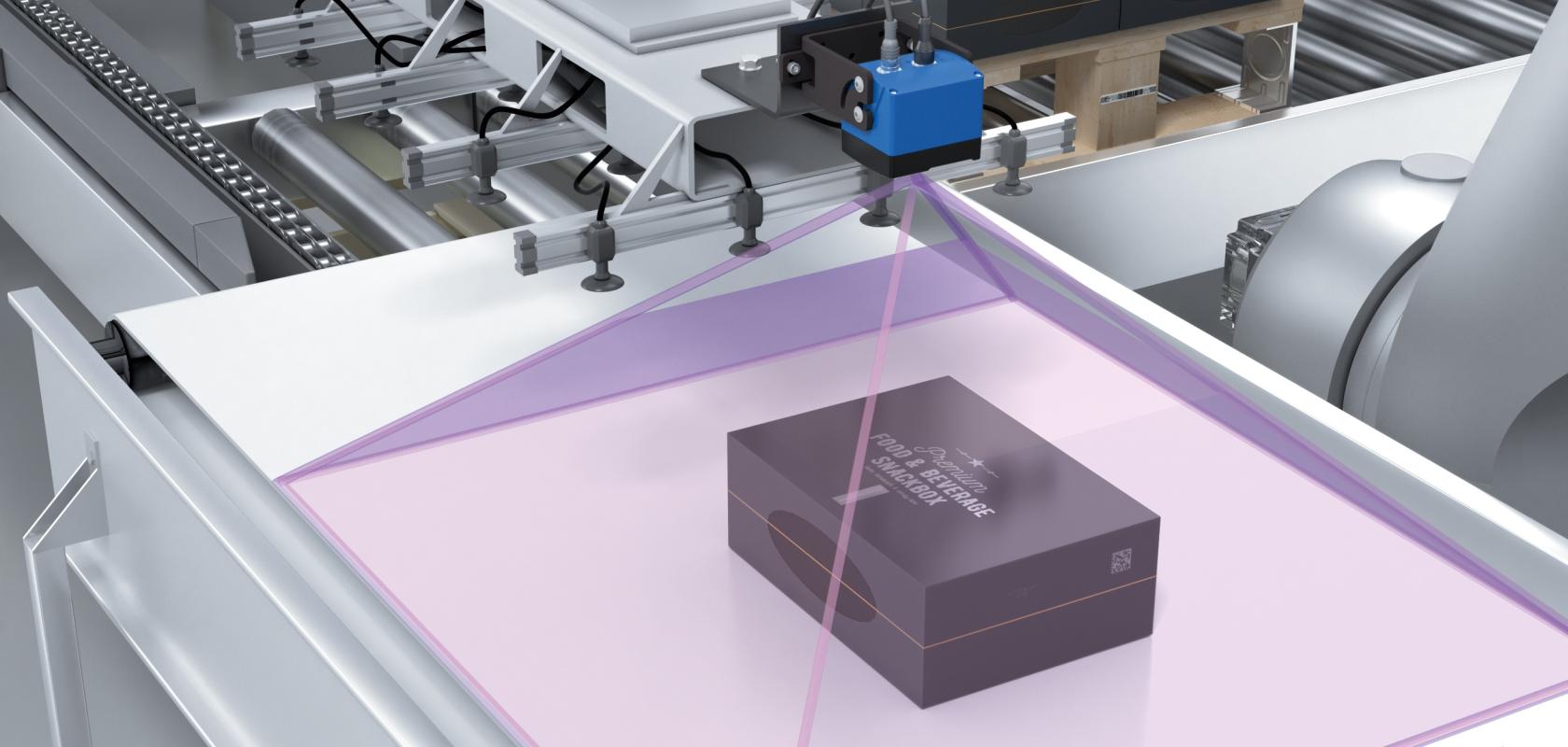

Configuring machine vision inspections in 3D is now possible in a snapshot, thanks to the combination of Sick’s Visionary-T Mini AP camera with the new Sick Nova 3D Presence Inspection sensorApp.

The Sick Visionary-T Mini AP uses time-of-flight snapshot technology for detailed environmental perception at rapid production speeds. It captures both the 3D depth and 2D intensity values of every pixel at an exceptional (512 × 424 px) resolution in a single shot of light, at up to 30 3D frames per second.

Common 3D inspection tasks in factory automation and logistics, such as completeness, fill level monitoring, or robot palletising, can be set up rapidly and cost-effectively to run onboard the Visionary-T Mini AP camera using the Sick Nova 3D Presence Inspection sensorApp. Users simply select the 3D machine vision tools they need via an easy graphic user interface and the Visionary-T Mini AP camera is soon delivering reliable inspection results via I/O to the machine controller or over TCP/IP.

With a toolset of commonly used 3D vision tools, the Sick Nova Presence Inspection App easily masters tasks like emptiness checks in bins, totes and crates, presence detection of objects in 3D scenes, as well as simple measurements and quality tolerance checks.

Using the Sick Nova Presence Inspection on Visionary T Mini, the position, height and volume of any package can be determined, for example for a robot to pick it and place it in a container or pallet. The Visionary-T Mini’s 3D snapshot technology can also be used for continuous 3D Fill Level monitoring, for example to determine if totes are empty, filled, full or overfull, or it can measure the presence of parts in a bin or presence of ingredients in a vessel, for example.

The Sick Visionary-T Mini CX provides an alternative option for customers wishing to use the power of the Visionary-T Mini’s snapshot technology to stream 3D data for their own software applications.